Blog

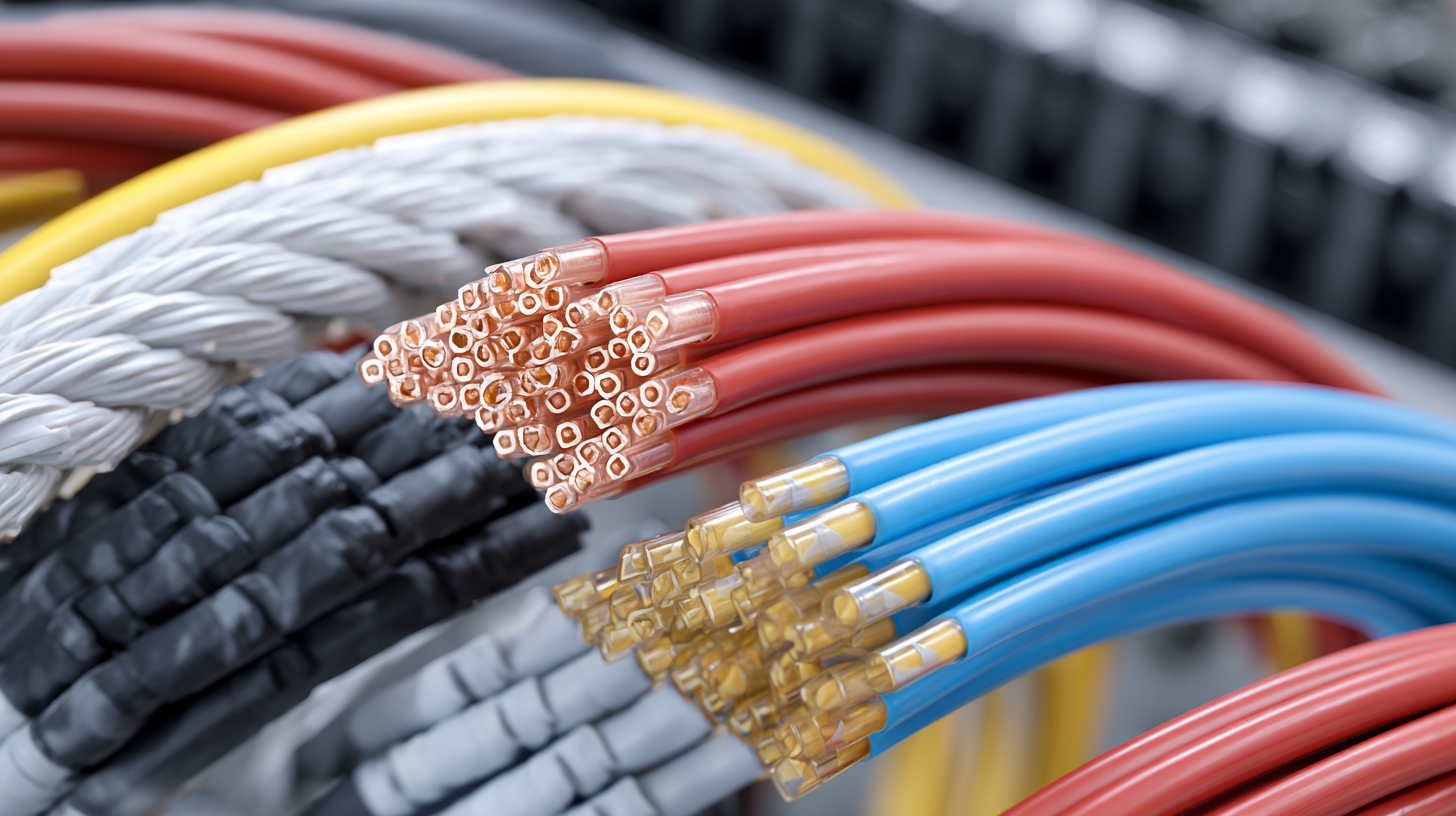

How to Select the Right Tray Cable for Your Electrical Installation Needs

In the world of electrical installations, the selection of the appropriate tray cable is crucial for ensuring safety, efficiency, and compliance with industry standards. According to the National Electrical Manufacturers Association (NEMA), the use of proper cable types can significantly reduce the risk of electrical faults and enhance overall system reliability.

Tray cables, designed for use in cable trays and ladder racks, offer a range of advantages, including flexibility and ease of installation, making them ideal for both commercial and industrial applications.

With the global market for electrical cables projected to reach approximately $305 billion by 2027, driven by increasing demand for infrastructural development and modernization, understanding how to choose the right tray cable becomes imperative for professionals in the field. This guide aims to provide insights and considerations for selecting the appropriate tray cable to meet specific installation needs, ultimately ensuring optimal performance and compliance with regulations.

Tray cables, designed for use in cable trays and ladder racks, offer a range of advantages, including flexibility and ease of installation, making them ideal for both commercial and industrial applications.

With the global market for electrical cables projected to reach approximately $305 billion by 2027, driven by increasing demand for infrastructural development and modernization, understanding how to choose the right tray cable becomes imperative for professionals in the field. This guide aims to provide insights and considerations for selecting the appropriate tray cable to meet specific installation needs, ultimately ensuring optimal performance and compliance with regulations.

Understanding the Types of Tray Cables Available for Electrical Installations

When selecting the right tray cable for your electrical installation needs, it’s crucial to understand the various types available in the market. Tray cables are typically classified into several categories, including ladder-type, perforated-type, and solid-bottom types. Each type has its unique features suited for different applications, and understanding these differences can help ensure the safety and efficiency of your electrical systems.

When choosing a tray cable, consider factors such as the environment where it will be installed. For instance, areas exposed to moisture may require cables with enhanced protection against corrosion and moisture ingress. Additionally, fire-resistant cables may be necessary for installations in high-risk fire areas. Furthermore, with the increasing demand in the wire and cable management market, innovations in materials and designs are becoming more prevalent, offering options that prioritize sustainability and durability.

Tips:

- Evaluate the specific requirements of your installation environment to choose the appropriate tray type that meets safety and functionality needs.

- Stay informed about new materials and technologies that enhance the performance and longevity of tray cables, especially with the anticipated growth in the market.

Key Factors to Consider When Choosing Tray Cables for Your Project

When selecting the appropriate tray cable for your electrical installation, several key factors must be considered to ensure both safety and efficiency. First and foremost, it is crucial to assess the environmental conditions where the cable will be installed.

Tray cables are often exposed to various elements, which means their insulation must withstand moisture, temperature variations, and potential chemical exposure. Choosing a cable with the right insulation material, such as PVC or XLPE, can significantly enhance its durability in challenging environments.

Another important consideration is the cable's size and ampacity. The specific electrical load that the cable needs to support will determine the appropriate gauge. It’s vital to consult the National Electrical Code (NEC) for guidelines on ampacity to avoid overheating and ensure optimal performance. Additionally, consider the layout of the installation—whether it will be in a cable tray, conduit, or exposed. This can affect the choice of cable type, as some designs are better suited for specific configurations, thus influencing installation efficiency and safety standards.

Comparing the Performance of Different Tray Cable Materials

When selecting tray cable for electrical installations, understanding the performance of different materials is crucial. For instance, PVC (Polyvinyl Chloride) is a cost-effective option that exhibits good resistance to moisture and chemicals, making it suitable for various indoor applications. A report from the National Electrical Manufacturers Association (NEMA) indicates that nearly 60% of installations in commercial settings favor PVC-trayed cables due to their balance of performance and affordability. However, while PVC offers good protection, it may not withstand extreme temperature fluctuations as effectively as other materials.

On the other hand, Low Smoke Zero Halogen (LSZH) cables have gained popularity in environments where fire safety is a priority. According to a study published by the International Electrotechnical Commission (IEC), LSZH cables release significantly lower amounts of toxic gas when exposed to fire, making them a safer choice for public spaces and high-rise buildings. This has resulted in a 20% increase in LSZH cable adoption in these settings over the past five years. In summary, while factors such as cost and application needs heavily influence cable selection, performance characteristics like flame resistance and chemical resilience should guide decisions to ensure safety and efficiency in electrical installations.

How to Select the Right Tray Cable for Your Electrical Installation Needs

| Cable Material | Temperature Rating (°C) | Voltage Rating (V) | Flexibility | Cost per Meter ($) |

|---|---|---|---|---|

| Copper | 90 | 600 | High | 1.50 |

| Aluminum | 90 | 600 | Medium | 1.00 |

| Copper-Clad Aluminum | 90 | 600 | High | 1.20 |

| XLPE Insulated | 90 | 1000 | High | 1.80 |

| PVC Insulated | 70 | 600 | Medium | 0.80 |

Best Practices for Installing Tray Cables Safely and Efficiently

When it comes to installing tray cables, safety and efficiency should be top priorities. One of the best practices for ensuring a successful installation is to carefully plan the layout before beginning. This includes assessing the cable’s routing path, considering the environment it will be placed in, and ensuring that the tray is appropriate for the cable type. Always adhere to the National Electrical Code (NEC) guidelines, which provide crucial information about spacing and load ratings for tray cables to prevent overheating and potential hazards.

Additionally, proper installation techniques can significantly improve both safety and efficiency. When securing the cables in the tray, use appropriate supports and fastening methods to prevent sagging or movement, which can lead to wear and tear over time. It's also essential to maintain adequate separation between different types of cables to minimize interference and ensure optimal performance. Finally, regular inspections and maintenance of the cable trays are essential to detect any potential issues early and to uphold safety standards throughout the lifespan of the electrical installation.

Common Mistakes to Avoid When Selecting Tray Cables for Your Needs

Choosing the right tray cable for electrical installations is crucial, yet many make common mistakes that can lead to suboptimal performance and safety hazards. One significant mistake is underestimating the ampacity requirements. According to the National Electrical Code (NEC), it's essential to ensure that the selected cable can handle the maximum load, factoring in ambient temperature and the number of conductors in the tray. Failure to do so can result in overheating and potential cable failure, as cables operating beyond their rated capacity can degrade in lifespan by up to 30%.

Another frequent error is ignoring the environmental conditions where the cable will be installed. For instance, using cables only rated for indoor use in outdoor or damp conditions can lead to insulation breakdown and increased risk of exposure to moisture-related issues. A study by the Institute of Electrical and Electronics Engineers (IEEE) indicates that improper cable selection in harsh environments can reduce operational efficiency by as much as 20%. Therefore, it is vital to consider factors such as exposure to chemicals, temperature fluctuations, and installation location when selecting tray cables to ensure reliability and compliance with industry standards.

Tray Cable Selection: Common Mistakes to Avoid

Related Posts

-

Quality Tray Cables from China: Elevating Global Standards with Exceptional Manufacturing

-

The Future of Plastic Cable Tray Innovations and Sustainability

-

How to Select the Right Basket Cable Tray for Your Wiring Needs

-

5 Best Reasons to Choose Fiberglass Cable Tray for Your Next Project

-

Ultimate Guide: How to Select the Right Flexible Cable Tray for Your Industrial Needs

-

Ultimate Guide to Choosing the Right Mesh Cable Tray for Your Project

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now