Blog

How to Select the Right Heavy Duty Cable Tray for Your Industrial Needs

Selecting the right heavy duty cable tray is crucial for ensuring the efficient management of electrical cabling and minimizing the risks associated with industrial operations. According to a report by MarketsandMarkets, the global cable tray market is projected to reach USD 4.80 billion by 2026, with a significant increase in demand driven by rapid industrialization and infrastructure development. Heavy duty cable trays not only support high volumes of electrical wiring but also provide robust protection against environmental factors and mechanical stress.

Understanding the specific requirements of your facility—such as weight load, material type, and compliance with safety standards—will enable your organization to make informed decisions, ultimately optimizing both safety and performance in your industrial applications. As the landscape of industrial operations evolves, equipping your facilities with the appropriate heavy duty cable tray is essential to achieving operational excellence.

Identifying the Specific Requirements for Your Electrical Cable Management System

When selecting the right heavy-duty cable tray for your industrial needs, it's essential to identify the specific requirements of your electrical cable management system. This involves assessing the size, weight, and type of cables that will be routed through the tray. Start by calculating the total number of cables, their diameters, and their combined weights. Heavy-duty trays are designed to hold significant loads, so understanding these specifications will help determine the appropriate tray and prevent future issues related to weight capacity.

In addition to capacity, consider the environmental conditions where the cable tray will be installed. Factors such as exposure to chemicals, temperature extremes, and moisture levels can significantly influence material selection. For example, galvanized steel trays offer durability in harsh conditions, while fiberglass trays can be better suited for environments prone to corrosion. By thoroughly evaluating these requirements, you can ensure that your cable management system is not only effective but also reliable and long-lasting.

Understanding Different Types of Heavy-Duty Cable Trays and Their Applications

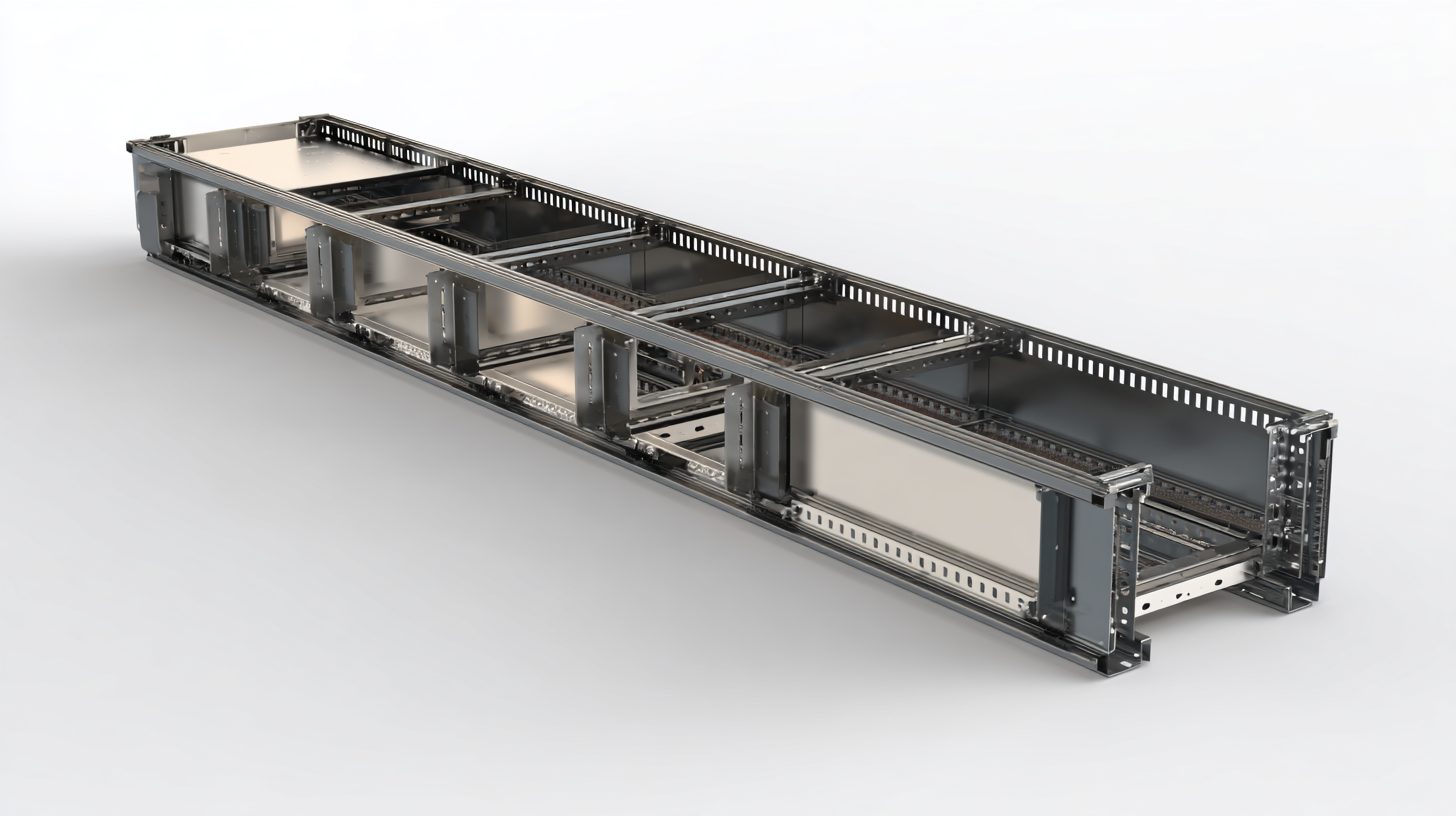

When it comes to selecting the right heavy-duty cable tray for your industrial needs, understanding the different types available is crucial. Heavy-duty cable trays come in various materials and designs, each suited for specific applications.

For instance, ladder trays offer excellent ventilation, making them ideal for environments where heat dissipation is critical. On the other hand, solid-bottom trays provide enhanced protection against dust and debris, perfect for manufacturing facilities where cleanliness is paramount.

Tips: Consider the environment where the cable tray will be installed. If your facility is exposed to moisture or chemicals, materials like fiberglass or stainless steel are more appropriate due to their corrosion resistance. Additionally, assess the weight and volume of the cables; choosing a tray that adequately supports the load is vital to ensure longevity and minimize maintenance.

Another option to explore is wire mesh trays, which offer flexibility and ease of installation. These trays are particularly useful in data centers where cabling can be reconfigured frequently.

Tips: Always prioritize trays with sufficient load-bearing capacities and ensure they meet the necessary industry standards for safety and performance.

Evaluating Material Options for Durability and Performance in Harsh Environments

When selecting heavy-duty cable trays for industrial applications, the choice of material is paramount, especially in harsh environments where durability and performance are critical. According to a report by the National Electrical Manufacturers Association (NEMA), approximately 30% of cable failures in industrial settings are attributable to inadequate environmental protection, emphasizing the significance of material choice. Common materials include steel, aluminum, and fiberglass, each offering unique benefits for specific conditions.

Steel, often galvanized or coated, provides exceptional strength and resistance to physical damage, making it suitable for high-impact environments. However, its susceptibility to corrosion in wet or chemical-laden atmospheres necessitates careful consideration. On the other hand, aluminum trays are lightweight and resistant to rust, offering a viable option for outdoor installations or coastal regions. A study published in the Journal of Industrial Engineering showed that fiberglass-reinforced plastic (FRP) trays exhibit superior performance in highly corrosive settings, maintaining structural integrity and prolonging service life by up to 30% compared to traditional materials. Selecting the right material not only ensures compliance with industry standards but also significantly impacts the longevity and reliability of cable management systems.

Considering Load Capacity and Weight Distribution in Your Cable Tray Selection

When selecting a heavy-duty cable tray for industrial applications, considering load capacity and weight distribution is crucial for ensuring optimal performance and safety. The load capacity refers to the maximum weight a cable tray can support without bending or failing. It is essential to evaluate the specific weights of cables and any additional components that will be placed on the tray. Factoring in variations in temperature and environmental conditions can also influence the tray's strength and durability.

Moreover, proper weight distribution is vital to prevent stress concentrations that could lead to premature failure. Distributing the weight evenly across the tray allows for better stability and minimizes the risk of sagging or structural damage. It is advisable to consult manufacturer specifications and guidelines to ensure the chosen tray meets the required standards for load capacity. Additionally, considering features such as tray width, material type, and configuration can help facilitate better weight distribution, leading to an effective and reliable cable management solution tailored to your industrial needs.

Assessing Installation and Maintenance Needs for Optimal Functionality

When selecting a heavy-duty cable tray for industrial applications, assessing installation and maintenance needs is crucial for ensuring optimal functionality. The installation process should be straightforward, allowing for efficient integration within existing infrastructure. Consider the layout of your facility and the specific pathways required for power and data cables. Factors such as the weight capacity of the tray, the materials used, and their compatibility with installation environments—like outdoor exposure or high temperatures—should influence your choice. Ensuring that your installation team has the necessary tools and knowledge can also facilitate a smoother process, ultimately saving time and resources.

Furthermore, ongoing maintenance plays a vital role in the longevity of cable trays. Selecting materials resistant to corrosion, abrasion, and other wear factors can minimize maintenance efforts. Accessible designs are essential to inspection and repairs; trays that allow for easy access to cables will reduce downtime during routine checks. Implementing a regular maintenance schedule and training personnel on best practices for cable management can significantly enhance the tray's performance. By prioritizing both installation and maintenance considerations, industries can ensure that their heavy-duty cable trays function optimally while supporting safety and efficiency in their operations.

Related Posts

-

How to Choose the Right Black Cable Tray for Your Wiring Needs

-

Understanding the Challenges of Wire Cable Tray Systems: Insights and Solutions from Industry Experts

-

Quality Tray Cables from China: Elevating Global Standards with Exceptional Manufacturing

-

How to Select the Right Tray Cable for Your Electrical Installation Needs

-

5 Best Cable Tray Wire Solutions for Efficient Wiring Management

-

Ultimate Guide to Choosing the Right Mesh Cable Tray for Your Project

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now