Blog

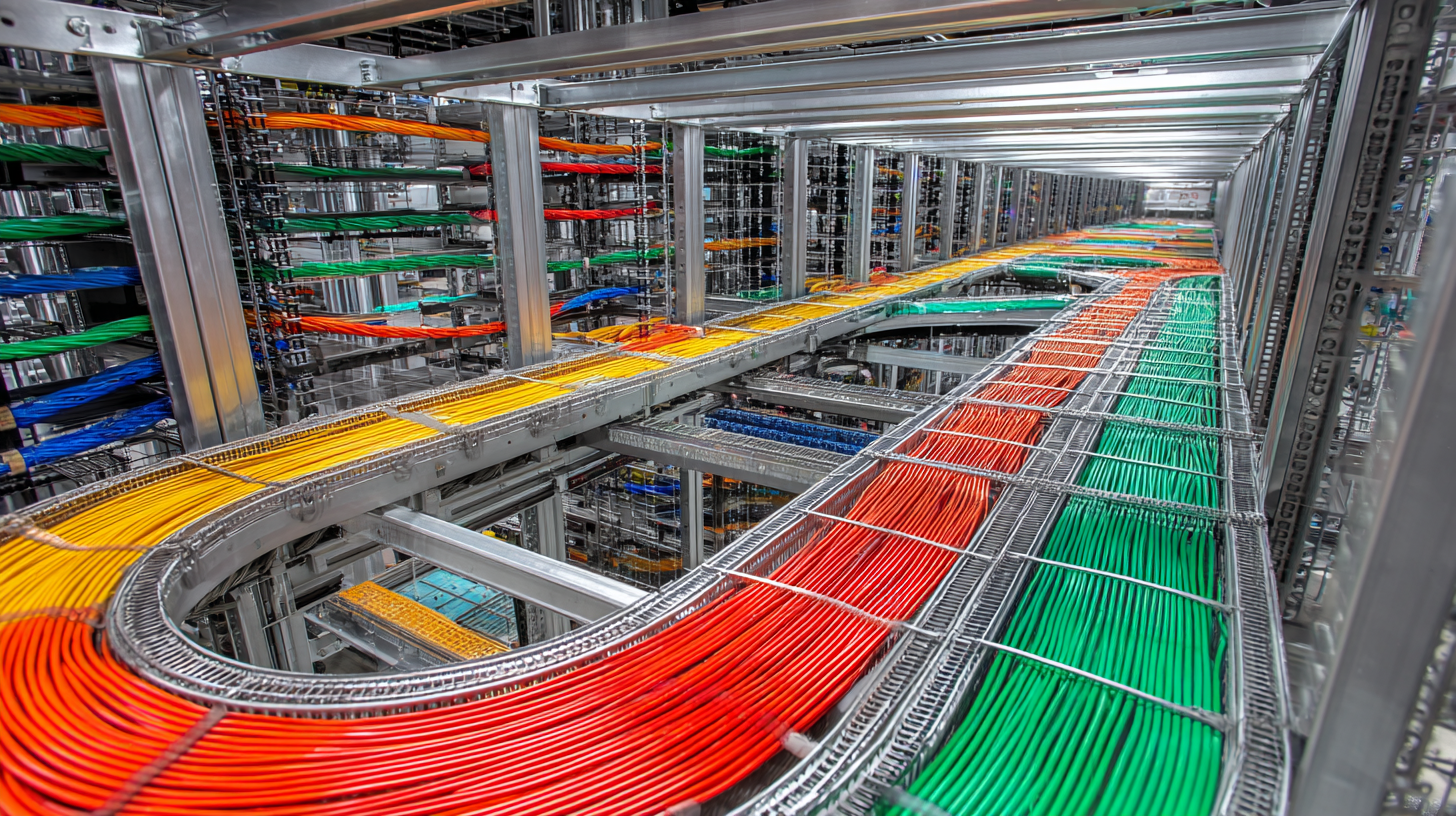

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

The cable tray wire industry is anticipated to witness significant growth in the coming years, with projections indicating an increase from USD 2.5 billion in 2023 to over USD 4.0 billion by 2025, according to a recent report by Global Market Insights. As businesses and industries strive for enhanced efficiency, the demand for superior cable management solutions has never been more critical.

Selecting the right cable tray wire manufacturer is therefore crucial not only to meet specific project requirements but also to ensure compliance with safety standards and prolong the lifespan of installations. With various factors influencing quality, durability, and cost-effectiveness, it is essential for stakeholders to stay informed about the latest industry trends and make educated choices.

This blog presents top tips for navigating the selection process, ensuring that your needs are met with the highest standards in the evolving landscape of cable tray wire solutions.

Understanding the Importance of Industry-Specific Certifications for Cable Tray Manufacturers

When selecting a cable tray wire manufacturer, one of the most crucial factors to consider is the existence of industry-specific certifications. These certifications serve as a testament to a manufacturer's commitment to quality, safety, and compliance with relevant standards. They not only reflect the reliability of the products but also assure customers that the manufacturer adheres to stringent industry regulations, which can significantly influence the performance and longevity of the cable trays in various applications.

In industries such as construction, telecommunications, and electrical engineering, the stakes are high, making it imperative to choose manufacturers with appropriate certifications. For instance, certifications from organizations like Underwriters Laboratories (UL) or the National Electrical Manufacturers Association (NEMA) can signal that the products have undergone rigorous testing for safety and performance. By prioritizing manufacturers with these credentials, businesses can mitigate risks associated with electrical installations and ensure a more effective implementation of their projects, ultimately translating into a safer and more efficient operational environment.

Evaluating Manufacturer’s Compliance with International Import and Export Standards

When selecting the best cable tray wire manufacturer, it's crucial to evaluate their compliance with international import and export standards. This aspect has become increasingly important in light of recent changes in global trade policies, such as India’s Foreign Trade Policy 2023, which emphasizes the need for adherence to regulatory requirements when engaging in international transactions. Manufacturers must demonstrate a solid understanding of these regulations, as failing to comply can lead to significant operational disruptions and potential penalties.

One of the key tips is to thoroughly investigate the manufacturer's certifications and their history with international compliance. Ensure that they are familiar with the required documentation and procedures for both importing and exporting their products. This knowledge is essential for mitigating risks associated with changing trade policies and tariffs, as highlighted by recent global developments. Additionally, consider requesting references or case studies that demonstrate the manufacturer’s ability to navigate complex regulatory environments successfully.

Moreover, assess the manufacturer’s commitment to quality assurance through regular audits and adherence to international standards. Reliable manufacturers not only comply with import and export regulations but also strive to maintain high standards in their processes and products. This proactive approach will help ensure that you select a partner who can meet your needs both domestically and in the global marketplace.

Compliance Evaluation of Cable Tray Wire Manufacturers

This chart shows the compliance rates of various cable tray wire manufacturers in relation to international import and export standards. A higher percentage indicates better adherence to these standards.

Key Considerations When Assessing Quality Control Processes in Wire Tray Production

When selecting a cable tray wire manufacturer, one vital aspect to evaluate is their quality control processes. Manufacturers with rigorous quality control measures ensure that the materials and production methods meet industry standards. You should inquire about their quality certifications, such as ISO 9001, which signifies adherence to international quality management principles. This certification not only reflects the manufacturer’s commitment to quality but also provides assurance that they consistently meet customer expectations.

Another critical consideration is the monitoring of production quality. Manufacturers that implement real-time quality checks throughout the production line can quickly identify defects and rectify issues before they escalate. Look for companies that utilize advanced inspection technologies like automated visual inspection systems and tensile testing equipment. These tools enhance the reliability of the products and help maintain high standards.

Lastly, effective communication regarding quality control processes is essential. A transparent manufacturer should be willing to share details about their quality assurance practices and address any concerns you may have. Ask about their feedback mechanisms for continuous improvement, as manufacturers that value customer input are more likely to deliver superior products tailored to your specific needs.

Comparing Material Options and Their Performance in Various Applications

When selecting the best cable tray wire manufacturer, understanding the material options available is crucial to ensure optimal performance in various applications. Different materials, such as steel, aluminum, and fiberglass, each bring unique benefits. For instance, steel is known for its strength and durability, making it a popular choice for heavy electrical installations. In contrast, aluminum is lightweight and resistant to corrosion, making it ideal for environments with high moisture levels.

One top tip is to consider the specific environment where the cable trays will be installed. If they are going to be exposed to harsh chemicals, opting for fiberglass could provide better longevity and resilience. Additionally, prioritize manufacturers that offer custom solutions tailored to your needs, which can enhance the effectiveness of the cable tray system significantly.

Another vital aspect is the performance rating of the materials under different conditions. Assessing thermal performance, load capacity, and resistance to impact can help in making an informed decision. A manufacturer that provides product testing data and certifications can give extra assurance regarding the quality and reliability of their products. Always ask for samples to evaluate the material personally before making a bulk purchase.

Seeking Customer Reviews and Recommendations for Reliable Manufacturer Selection

When selecting a cable tray wire manufacturer, one of the most critical steps is seeking customer reviews and recommendations. According to a recent report by Research and Markets, the global cable management market is projected to grow at a CAGR of 6.3% from 2021 to 2026, highlighting the increasing demand for reliable and high-quality manufacturers. Reviews from past customers offer invaluable insights into a manufacturer’s quality, reliability, and customer service, allowing potential buyers to make informed decisions.

Platforms such as Trustpilot and Google Reviews can serve as excellent resources for assessing feedback on manufacturers. A study by Nielsen found that 92% of consumers trust recommendations from friends and family more than any other form of advertising, underscoring the weight that personal recommendations carry in the decision-making process. Engaging with industry forums and social media platforms can also lead to authentic testimonials and help identify manufacturers that consistently meet or exceed customer expectations. Through diligent research and the analysis of customer feedback, businesses can find a cable tray wire manufacturer that aligns perfectly with their specific needs.

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

| Manufacturer Type | Location | Customer Rating | Average Lead Time (weeks) | Key Features |

|---|---|---|---|---|

| Local Manufacturer | USA | 4.5/5 | 2 | Customization options, Fast service |

| International Manufacturer | China | 4.0/5 | 4 | Competitive pricing, High volume capabilities |

| Specialized Manufacturer | Germany | 4.8/5 | 3 | Innovative design, Durable materials |

| Budget Manufacturer | India | 3.8/5 | 6 | Cost-effective solutions, Basic options |

| Premium Manufacturer | Italy | 4.7/5 | 3 | High-quality materials, Artisan craftsmanship |

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now