Blog

How to Select the Right Basket Cable Tray for Your Wiring Needs

In the ever-evolving landscape of electrical wiring and installation, selecting the right components is crucial for efficiency, safety, and long-term performance. Among these components, the basket cable tray has emerged as a preferred choice for supporting and organizing cables in commercial and industrial settings. According to the National Electrical Contractors Association (NECA), the use of cable management systems like basket cable trays can reduce installation time by up to 30%, while significantly improving accessibility and reducing the risk of cable damage. Additionally, a report from the Global Cable Tray Market Analysis projects that the demand for cable trays, particularly basket cable trays, will witness a compound annual growth rate (CAGR) of 5.6% from 2021 to 2026. With these compelling statistics, it becomes imperative for professionals to understand how to select the appropriate basket cable tray that meets specific wiring needs, ensuring both compliance with safety standards and optimal performance.

Understanding Different Types of Basket Cable Trays for Efficient Wiring Solutions

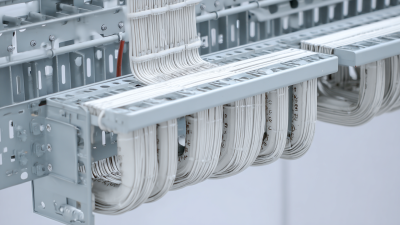

When it comes to wiring solutions, selecting the right type of basket cable tray is crucial for efficiency and organization. Basket cable trays come in various forms, each designed to cater to specific wiring needs. For instance, mesh wire baskets are ideal for light to medium cable loads and allow for excellent airflow, preventing overheating. They’re commonly used in commercial buildings where easy access to cables is needed for maintenance and expansion.

On the other hand, solid-bottom cable trays provide greater support for heavier cable loads and are better suited for environments that require some level of protection from dust or debris. These trays can be used in industrial settings where robust support and durability are paramount. Additionally, there are also adjustable and modular basket trays available in the market, which give you the flexibility to adapt to changing wiring requirements. Understanding these different types ensures you choose the right cable tray that meets your specific needs, ultimately leading to a more efficient wiring solution.

On the other hand, solid-bottom cable trays provide greater support for heavier cable loads and are better suited for environments that require some level of protection from dust or debris. These trays can be used in industrial settings where robust support and durability are paramount. Additionally, there are also adjustable and modular basket trays available in the market, which give you the flexibility to adapt to changing wiring requirements. Understanding these different types ensures you choose the right cable tray that meets your specific needs, ultimately leading to a more efficient wiring solution.

Key Factors to Consider When Choosing Basket Cable Trays for Your Project

When selecting basket cable trays for your wiring needs, there are several key factors to consider. First, evaluate the specific requirements of your project, including the type and amount of cabling you plan to install. Basket cable trays come in various sizes and load capacities, so understanding your project’s specifications will help you choose the right tray that can support your cables without risk of damage.

Tip: Always check for compatibility with your existing infrastructure. Ensure that the basket cable trays you choose can be easily integrated with other systems in your building. This includes considering the materials used in construction, as well as the environmental conditions they will be exposed to, such as humidity or temperature variations.

Another important factor is the installation process. Some cable trays may be more user-friendly than others, depending on the design and accessories needed for installation. A tray that is easy to install can save time and labor costs.

Tip: Research the available installation options and choose a tray that allows for flexible mounting configurations. This can be particularly helpful if your project requires adjustments or changes during installation.

Comparing Material Options for Basket Cable Trays: Steel, Aluminum, and More

When selecting the right basket cable tray for your wiring needs, one of the most critical factors to consider is the material composition. The two most popular options are steel and aluminum, each with its own set of advantages and drawbacks. Steel cable trays are known for their strength and durability, making them ideal for heavy-duty applications and harsh environments. However, they are more susceptible to corrosion, which can compromise their longevity if not properly treated. A galvanized steel finish can mitigate this issue, making it a viable option for indoor installations and environments with lower moisture levels.

On the other hand, aluminum basket cable trays offer excellent corrosion resistance, making them suitable for outdoor use and damp environments. They are lightweight and easier to install, which can save costs in labor. Although they generally come at a higher initial price point than their steel counterparts, the long-term savings on maintenance and replacement can make aluminum an appealing choice. Additionally, specialized materials like fiberglass or stainless steel trays are available for specific applications where unique environmental or structural requirements exist. Ultimately, assessing the specific needs of your project will guide you in selecting the most appropriate material for your basket cable tray.

Material Comparison for Basket Cable Trays

Installation Tips and Best Practices for Optimal Cable Management

When it comes to optimal cable management, the installation of basket cable trays is crucial. Industry reports reveal that effective cable management can enhance system performance and prolong equipment life. A well-designed cable tray system allows for proper ventilation, reducing the risk of overheating, which can lead to system failures. The National Electrical Manufacturers Association (NEMA) reports that 30% of electrical failures can be attributed to poor cable management practices.

To ensure a successful installation, it's important to follow best practices. First, consider the load capacity required for your specific wiring needs; improper sizing can lead to safety hazards and increased maintenance costs. The Electrical Contractor Association suggests maintaining a minimum clearance of 1.5 inches below the cables for optimal airflow. Additionally, adhere to local codes and standards, such as the National Electrical Code (NEC), to ensure compliance and safety. Regular inspections and maintenance can also prolong the life of your cable trays and improve overall efficiency, aligning with data from the International Electrical Testing Association (IETA), which highlights that preventive maintenance strategies can reduce downtime by up to 40%.

Maintaining Safety Standards and Compliance with Basket Cable Tray Systems

When selecting the right basket cable tray for your wiring needs, it is crucial to prioritize safety standards and regulatory compliance. Recent incidents, such as an electrician injury during the pulling of electrical cables, underscore the importance of using safe and compliant cable management systems. A well-designed cable tray not only organizes and protects cables but also mitigates risks associated with electrical installations. Ensuring that your chosen tray system meets applicable industry standards can significantly reduce the chances of accidents and facilitate a smoother workflow on site.

The rise in the cable tray market highlights a growing awareness of these safety measures among contractors and electricians. With innovations like retrofit devices for noncompliant or overloaded trays, businesses can adapt existing systems to meet current standards and enhance safety. As the industry evolves, understanding the specifications and compliance requirements will be essential. Investing in a cable tray system that integrates well with modern practices not only ensures adherence to safety regulations but also expedites installation and maintenance processes, allowing for efficient and effective management of wiring infrastructure.

How to Select the Right Basket Cable Tray for Your Wiring Needs

| Feature | Description | Safety Standard | Load Capacity (lbs) |

|---|---|---|---|

| Material | Steel, Aluminum, or Plastic options | ASTM A123/A123M | 200 |

| Tray Width | Available in various widths from 6" to 36" | NEMA VE 1 | 150 |

| Finish Type | Galvanized, Stainless Steel, or Powder Coated | ANSI/NFPA 70 | 300 |

| Installation Method | Surface-mounted or suspended | OSHA regulations | 250 |

| Usage Type | Indoor or Outdoor applications | UL 2043 | 350 |

Related Posts

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

The Future of Plastic Cable Tray Innovations and Sustainability

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

-

Understanding the Challenges of Wire Cable Tray Systems: Insights and Solutions from Industry Experts

-

Ultimate Guide: How to Select the Right Flexible Cable Tray for Your Industrial Needs

-

5 Best Cable Tray Wire Solutions for Efficient Wiring Management

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now