Blog

Exploring the Future of Fiberglass Cable Trays at the 138th China Import and Export Fair 2025

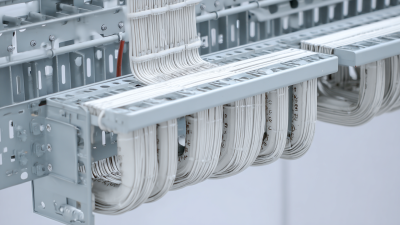

The rapid advancement of technology and the increasing demand for durable and efficient cable management solutions have positioned fiberglass cable trays at the forefront of modern infrastructure development. According to a recent industry report by MarketsandMarkets, the global fiberglass cable tray market is projected to grow at a CAGR of 6.4% from 2020 to 2025, driven by the rising adoption of lightweight, high-strength materials in construction and industrial applications. At the upcoming 138th China Import and Export Fair in 2025, stakeholders will gather to explore innovative fiberglass cable tray designs that promise enhanced performance and sustainability. This event will showcase cutting-edge developments in the field, highlighting how fiberglass cable trays are becoming the preferred choice for electrical installations across a variety of sectors, including telecommunications, power generation, and data centers. As the industry evolves, the focus will inevitably shift towards environmentally friendly solutions that do not compromise on performance, setting the stage for an exciting future in the realm of cable management systems.

Future Trends in Fiberglass Cable Tray Demand and Market Growth Projections for 2025

As we approach the 138th China Import and Export Fair in 2025, the spotlight on fiberglass cable trays is becoming more pronounced. The demand for fiberglass cable trays is expected to soar due to their durability, corrosion resistance, and lightweight properties. Industries such as construction, telecommunications, and renewable energy are increasingly adopting fiberglass solutions, leading to significant market growth. Projections indicate that the market will expand at a remarkable rate, driven by the ongoing shift towards greener and more sustainable materials in construction and industrial applications.

Tip: When investing in fiberglass cable trays, consider the specific environmental conditions of your project site. Selecting trays that are engineered to withstand chemical exposure, temperature fluctuations, and mechanical stresses will enhance longevity and protect investment.

Innovation in the design and manufacturing processes of fiberglass cable trays is also set to shape future trends. Advances in technology are making it possible to produce lighter yet stronger trays that can accommodate more complex wiring needs. Additionally, manufacturers are focusing on eco-friendly production methods, which could further enhance their appeal in the market.

Tip: Engage with manufacturers who emphasize sustainability in their production processes. This not only benefits the environment but can also lead to tax breaks or incentives for using eco-friendly materials in your projects.

Innovations in Fiberglass Cable Tray Manufacturing Processes at the 138th China Import and Export Fair

At the 138th China Import and Export Fair in 2025, innovations in fiberglass cable tray manufacturing processes are set to take center stage. This pivotal event highlights advancements that enhance efficiency, reduce costs, and improve the overall sustainability of production methods in the electrical infrastructure industry. Recent industry reports indicate that the fiberglass cable tray market is anticipated to grow significantly, driven by demands for lightweight, corrosion-resistant solutions that meet modern building standards.

As manufacturers showcase their latest offerings, it’s essential for buyers to consider not just the products themselves but the manufacturing processes behind them. Innovations such as automated production lines and advanced materials can lead to enhanced product performance and decreased environmental impact.

**Tip:** When evaluating fiberglass cable trays, look for products that highlight their sustainability credentials and the technologies used in their manufacturing.

Moreover, as the market evolves, staying updated with emerging trends like smart manufacturing and robotics integration will be crucial. These technologies not only streamline operations but also create opportunities for increased customization in cable tray solutions, responding effectively to the diverse needs of global infrastructure projects.

**Tip:** Engage with exhibitors who are pioneering these technologies to learn more about how they can benefit your projects.

Innovations in Fiberglass Cable Tray Manufacturing Processes

Environmental Impact and Sustainability of Fiberglass Cable Trays in Industrial Applications

At the 138th China Import and Export Fair in 2025, the spotlight on fiberglass cable trays emphasizes their role in promoting environmental sustainability within industrial applications. Recent industry reports indicate that fiberglass cable trays can reduce carbon emissions by up to 35% compared to traditional metal options due to their lightweight nature and lower energy consumption during production. This reduction aligns with global sustainability goals, urging businesses to adopt eco-friendly materials in their operations.

Moreover, fiberglass cable trays are highly resistant to corrosion and degradation, which significantly extends their lifespan and reduces the need for frequent replacements. According to the International Fiberglass Association, these trays can last up to 30 years in harsh environments, minimizing waste generated from disposal and manufacturing of replacements. This durability not only supports sustainability efforts but also leads to cost savings for industries, as maintenance and replacement costs are significantly lower. As the industrial sector increasingly prioritizes environmental responsibility, fiberglass cable trays emerge as a practical and sustainable choice for infrastructure development.

Competitive Landscape: Major Players and Investment Opportunities in Fiberglass Cable Trays

The fiberglass cable tray market is experiencing significant growth, with a projected increase from $253.48 million in 2019 to an estimated $696.78 million by 2032. This represents a compound annual growth rate (CAGR) of 8.36% during the forecast period. Such robust growth indicates a rising demand for efficient cable management solutions in various sectors, including construction, telecommunications, and industrial applications. As sustainability and efficiency become paramount, fiberglass cable trays are emerging as a preferred choice due to their lightweight nature, corrosion resistance, and durability.

In the competitive landscape, several key players are positioning themselves to capitalize on investment opportunities within the fiberglass cable tray sector. The U.S. electrical conduit market, valued at $1.72 billion in 2024, is also showcasing growth, with a projected CAGR of 4.17% through 2032. In tandem, the cable duct market is expected to reach $13.3 billion by 2032, growing at a CAGR of 7.8%. Such growth across related markets highlights a fertile environment for stakeholders, suggesting a ripe opportunity for investments and strategic partnerships to leverage advancements in fiberglass technology and meet evolving industry demands.

Technological Advancements: Smart Fiberglass Cable Trays and Their Role in the Future of Infrastructure

The 138th China Import and Export Fair 2025 offers a unique platform to showcase the latest technological advancements in fiberglass cable trays, particularly focusing on their integration into smart infrastructure. The rise of smart cities requires robust and adaptable solutions, and fiberglass cable trays are at the forefront due to their lightweight, corrosion-resistant properties and flexibility in design. These trays facilitate efficient cable management, ensuring that urban infrastructure supports the growing demands for data and electricity transmission.

Incorporating smart features into fiberglass cable trays presents exciting possibilities. For instance, integrating sensors can help monitor environmental conditions and detect potential hazards such as overheating, allowing for preemptive maintenance. Moreover, the ability to connect these trays with IoT devices enhances their functionality, enabling real-time tracking of cable systems’ health and performance. As industries evolve, these smart fiberglass cable trays are expected to play a crucial role in supporting sustainable and efficient infrastructure, ultimately paving the way for the next generation of urban planning and development.

Related Posts

-

How to Choose the Right Black Cable Tray for Your Wiring Needs

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

-

The Future of Plastic Cable Tray Innovations and Sustainability

-

Ultimate Guide: How to Select the Right Flexible Cable Tray for Your Industrial Needs

-

How to Select the Right Basket Cable Tray for Your Wiring Needs

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now