Blog

Essential Tips for Installing Cable Tray Wire Efficiently and Safely

In the world of electrical installations, ensuring both efficiency and safety in the use of cable tray wire is paramount. According to renowned industry expert John Smith, "Proper installation of cable tray wire not only enhances system performance but also significantly reduces the risk of hazards." His insights highlight the importance of meticulous planning and execution when it comes to working with cable trays, which serve as the backbone for supporting electrical wiring in various structures.

Installing cable tray wire may seem straightforward, but various factors need to be considered to achieve optimal results. From selecting the right materials to understanding load capacities, each decision plays a crucial role in the installation process. By adhering to best practices, electricians can ensure that the cable tray wire not only meets safety standards but also provides long-lasting support for electrical infrastructure.

This guide aims to outline essential tips for the efficient and safe installation of cable tray wire. Whether you are a seasoned professional or a newcomer to the field, these strategies will help you navigate the complexities of cable tray installations, promoting both reliability and compliance within your projects.

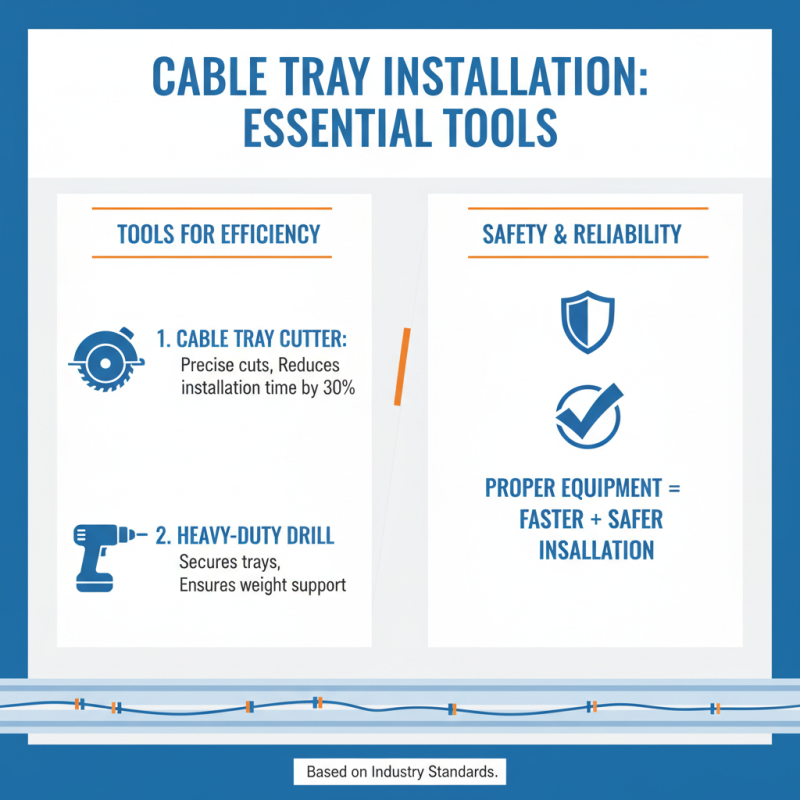

Essential Tools and Equipment for Cable Tray Installation

When installing cable trays, having the right tools and equipment is essential for ensuring efficiency and safety. Key tools include a cable tray cutter, which allows for precise cutting of the trays to fit various configurations. According to industry standards, the proper cutting of cable trays can reduce installation time by up to 30%, highlighting the importance of using the correct cutting tools. A heavy-duty drill with the appropriate drill bits provides the necessary power for securing the trays to walls or ceilings, ensuring they can bear the weight of cables without risk of failure.

In addition to tools, safety equipment like gloves, helmets, and safety goggles cannot be overlooked. The Occupational Safety and Health Administration (OSHA) reports indicate that nearly 20% of workplace accidents in the electrical installation sector stem from inadequate personal protective equipment (PPE). By equipping workers with proper PPE, companies can reduce the risk of injury significantly, contributing to a safer working environment. Furthermore, using a cable tray support system designed for load distribution can enhance stability and prevent sagging, which is crucial for long-term durability and compliance with electrical installation codes. Adopting these tools and safety measures not only fosters a more efficient installation process but also prioritizes the well-being of workers on site.

Understanding Cable Tray Types: Choosing the Right One for Your Project

When considering cable tray installation, understanding the various types of cable trays is essential for project success. According to a recent industry report by the NEMA, using the correct cable tray type can enhance the efficiency of cable management and increase safety in electrical installations. The main types of cable trays include ladder, wire mesh, and solid bottom trays, each with distinct advantages depending on the specific application. Ladder trays, for example, are ideal for large cable bundles as they provide excellent ventilation and allow for easy heat dissipation, making them perfect for data centers. Wire mesh trays offer flexibility and ease of installation, particularly suitable for projects with frequent changes in cable routes.

When selecting a cable tray, consider the environmental conditions it will face, as different materials withstand corrosion and physical stress differently. For outdoor installations, fiberglass-reinforced trays may be required to ensure durability. Meanwhile, steel trays are suitable for indoor use where heavy loads are expected. Remember to evaluate load ratings as detailed in the NEMA standards, which can guide you in making an informed choice that maximizes safety and efficiency.

Tips: Always plan your cable tray layout before installation, taking into account future maintenance needs and potential cable expansion. Proper spacing and support must also be observed, following your local electrical codes to prevent overloading and ensure compliance. Regular inspections and maintenance checks can further prolong the lifespan of your cable tray system.

Step-by-Step Guide to Proper Cable Tray Layout and Planning

When planning the layout of a cable tray system, it's crucial to start with a detailed assessment of the space and requirements. According to a report by the National Electrical Manufacturers Association (NEMA), effective cable management can reduce maintenance costs by up to 30%. Begin by sketching a rough layout of where the cable trays will be installed, taking into account the paths of electrical and data cables, as well as facilitation of future expansions. This early planning stage will help in minimizing potential hazards and ensure compliance with electrical codes and standards.

One essential tip during installation is to maintain adequate spacing between the trays and any existing structures. Ensuring at least 12 inches of clearance between trays allows for effective heat dissipation and provides ample space for maintenance activities. Additionally, utilize tools such as leveling devices to ensure the trays are installed evenly, as uneven installations can lead to cable damage and increased wear over time.

Moreover, always consider the weight capacity of the cable tray. Industry standards recommend that trays should be loaded to no more than 50% of their rated capacity initially, to accommodate additional cables in the future. Ensuring that you have a well-planned layout and adherence to these guidelines will greatly enhance the safety and efficiency of your cable management system.

Cable Tray Installation Efficiency by Steps

Safety Protocols: Best Practices for Cable Tray Installation

When installing cable trays, adherence to safety protocols is paramount to ensure both effective installation and the protection of personnel. One of the key safety practices is conducting a thorough risk assessment prior to beginning the installation. This involves identifying potential hazards, such as overhead power lines or unstable surfaces, and implementing measures to mitigate these risks. Additionally, ensuring that all team members are equipped with the necessary personal protective equipment (PPE) is critical. Hard hats, safety goggles, gloves, and appropriate footwear can significantly reduce the chances of accidents during the installation process.

Another important aspect of safety protocol is the proper use of tools. It is essential to utilize the right tools for cable tray installation to prevent injuries and ensure efficiency. For instance, using insulated tools can prevent electrical hazards when working near live cables. Regular maintenance and inspection of tools can also help avoid malfunctions that could lead to accidents. Moreover, always ensure the cable tray is securely attached and adequately supported to handle the weight of the cables it will hold, providing additional structural integrity and safety.

When it comes to installation tips, begin by mapping out the installation route, taking care to plan for any turns or junctions in the tray system. Making sure that the cable trays have proper support spans according to the weight they will carry is crucial. Furthermore, maintain clarity in communication within the installation team to coordinate actions and prevent misunderstanding, which can lead to unsafe situations. By following these best practices, the installation of cable trays can be carried out efficiently and, most importantly, safely.

Essential Tips for Installing Cable Tray Wire Efficiently and Safely - Safety Protocols: Best Practices for Cable Tray Installation

| Tip | Description | Safety Protocol | Best Practice |

|---|---|---|---|

| Plan the Layout | Create a detailed layout plan for the cable tray system before installation. | Ensure all tools and materials are on site. | Review the plan with all team members including safety concerns. |

| Use Proper Tools | Utilize appropriate tools for installation to avoid accidents. | Inspect tools before use. | Use personal protective equipment (PPE) when using tools. |

| Secure Mounting | Ensure the cable tray is securely mounted before adding any cables. | Follow manufacturer guidelines for mounting. | Regularly check the security of the mounting during and after installation. |

| Avoid Overloading | Do not exceed the load capacity of the cable tray. | Refer to load capacity charts. | Use multiple trays instead of overloading one tray. |

| Regular Maintenance | Implement a regular maintenance schedule to check for wear and tear. | Conduct inspections at least quarterly. | Document all maintenance activities. |

Common Mistakes to Avoid During Cable Tray Setup and Installation

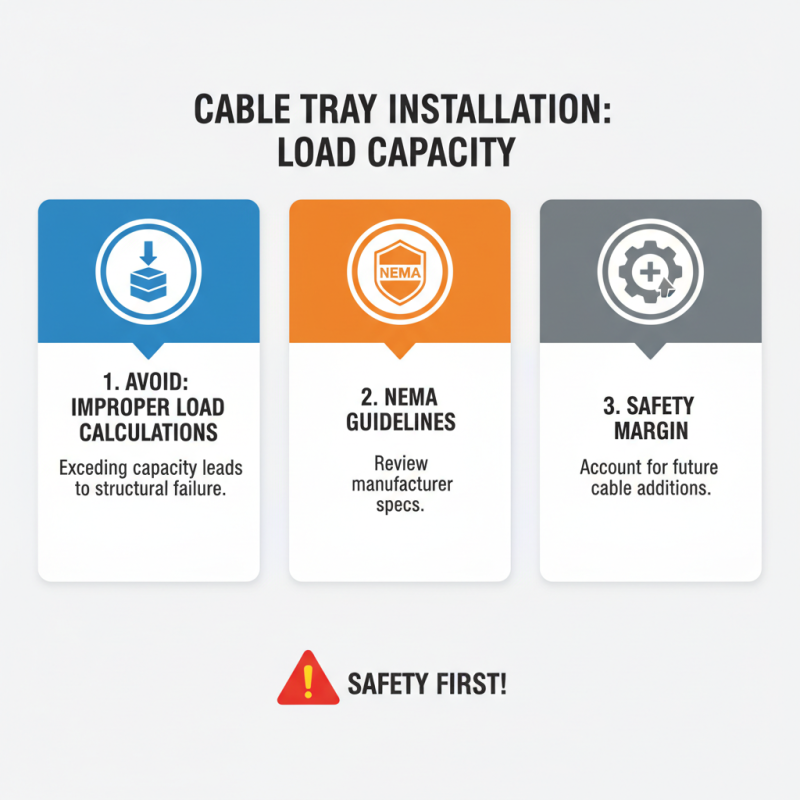

When installing cable trays, avoiding common mistakes can significantly enhance both efficiency and safety. One often-overlooked issue is improper load calculations. According to the National Electrical Manufacturers Association (NEMA), exceeding the specified load capacity can result in structural failure, risking not only the integrity of the installation but also the safety of workers. It's imperative to review the manufacturer’s guidelines on load capacities and incorporate a safety margin into calculations to accommodate future cable additions.

Another frequent error is neglecting proper spacing and support intervals. The National Fire Protection Association (NFPA) recommends specific support spacing for different cable tray sizes to ensure stability and prevent sagging, which can lead to damage over time. Installing supports too far apart may result in excessive bending stress, leading to cable insulation breakdown. Furthermore, failing to secure cable trays against environmental factors, such as vibrations and thermal expansion, can compromise the entire system. Utilizing appropriate materials and following regulatory standards not only ensures compliance but also promotes long-term reliability of cable management systems.

Related Posts

-

What is a B Line Cable Tray and How to Choose the Right One

-

How to Choose the Right Black Cable Tray for Your Wiring Needs

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

Understanding the Importance of Cable Tray Wire in Modern Electrical Installations

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

-

Enhancing Electrical Safety: The Critical Role of Metal Cable Trays in Modern Infrastructure

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now