Blog

How to Choose the Right Wire Cable Tray for Your Needs?

Choosing the right wire cable tray is crucial for effective cable management. The global cable tray market is projected to grow to $5.1 billion by 2027, reflecting increasing demand for better organization in various industries. Properly selected wire cable trays can prevent cable damage and enhance safety in electrical systems.

In many installations, the wrong choice can lead to issues. For instance, inadequate tray size may cause overheating, while improper materials may corrode over time. Industry reports show that nearly 25% of electrical failures stem from poor cable management. This statistic highlights the need for thoughtful selection of wire cable trays.

Considering factors like material, size, and load capacity is vital. Each project is unique, with specific conditions and demands. The right wire cable tray not only meets the technical needs but also aligns with industry standards. Investing time in this decision can significantly impact operational efficiency and reliability.

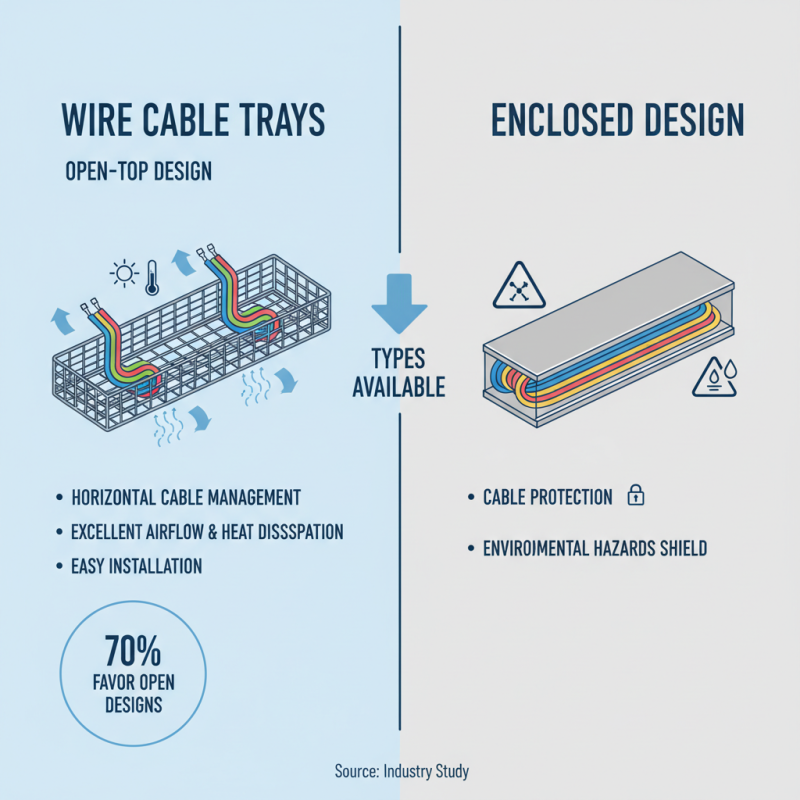

Types of Wire Cable Trays and Their Applications

When selecting a wire cable tray, understanding the types available is crucial. Open cable trays are widely used for horizontal cable management. They provide excellent airflow and heat dissipation. A study indicated that 70% of facilities favor open designs for their flexibility and ease of installation. However, they may expose cables to environmental hazards.

Ladder cable trays are another popular choice. They offer robust support for heavier cables. Their design allows for more significant weight-bearing capacity. According to industry reports, these trays can support 50-80% more weight than standard models. While ladder trays can be expensive, they are often necessary for industrial settings.

While choosing a cable tray, consider your specific requirements. Not every option suits every environment. Some locations might benefit from solid-bottom trays, which protect cables from moisture. On the other hand, those seeking budget-friendly solutions might hesitate at premium models, only to face higher maintenance costs later. It’s essential to balance cost, functionality, and safety in these decisions.

Factors to Consider When Selecting a Wire Cable Tray

When selecting a wire cable tray, several factors come into play. The size of the tray is essential. Too small, and cables may overcrowd. Too large, and it may waste space. Consider the diameter and number of cables you will install.

Material choice is equally important. Steel offers strength. Aluminum is lightweight and resistant to corrosion. Think about your environment. Indoor spaces may have different needs than outdoor setups.

Tips: Assess your installation location carefully. Environmental conditions can affect your tray’s longevity. Also, plan for future expansions. You don’t want to reroute everything again. Ensure compatibility with your wiring systems.

Lastly, check for local regulations. They can dictate safety standards. Ignoring them can lead to problems down the line. Evaluate your options thoughtfully before making a decision.

Factors to Consider When Selecting a Wire Cable Tray

Material Options for Wire Cable Trays: Pros and Cons

When selecting wire cable trays, material choice is crucial. Common options include steel, aluminum, and fiberglass. Each material has its own advantages and drawbacks. Steel is durable and strong, but it can rust. Aluminum is lightweight and resistant to corrosion but may not support heavy loads. Fiberglass offers great insulation properties but can be more expensive.

Steel trays are often used in industrial settings due to their strength. They hold up well in high-traffic areas. However, needing maintenance due to corrosion is a downside. Aluminum trays are easier to install. They are also lighter, making them suitable for various environments. Yet, their inability to handle excessive weights can be limiting.

Fiberglass trays are perfect for environments that require resistance to harsh chemicals. They don't corrode, but their higher cost can be a drawback for budget-conscious projects. Choosing the right material involves weighing these factors. Consider your specific needs carefully. Think about the environment where the trays will be used. Each choice presents unique challenges and rewards to consider.

Sizing Your Wire Cable Tray for Optimal Performance

When choosing a wire cable tray, sizing is crucial for optimal performance. The size must match the volume of wires you plan to install. A tray that is too small leads to crowding and heat issues. On the other hand, an oversized tray can waste materials and space.

Consider the fill ratio while sizing your tray. Ideally, it should not exceed 50% of its capacity. This prevents overheating and allows for easy maintenance. It is important to think about the future as well. You might need to add more cables later. Thus, planning ahead is wise.

Measure your cables carefully. Account for different cable types and their diameters. Each type has its unique space requirements. Sizes can vary significantly. Keeping a detailed inventory can help avoid mistakes. It's easy to overlook details, but they have a big impact on performance. Evaluate your needs and adjust before making your final decision.

How to Choose the Right Wire Cable Tray for Your Needs? - Sizing Your Wire Cable Tray for Optimal Performance

| Tray Type | Material | Width (inches) | Height (inches) | Load Capacity (lbs) | Application Area |

|---|---|---|---|---|---|

| Ladder Tray | Steel | 12 | 4 | 1000 | Data Centers |

| Solid Bottom Tray | Aluminum | 16 | 6 | 800 | Industrial |

| Wire Mesh Tray | Galvanized Steel | 14 | 4 | 600 | Commercial |

| Perforated Tray | Stainless Steel | 10 | 3 | 500 | Telecommunications |

| Cable Channel | PVC | 8 | 2 | 300 | Residential |

Installation Tips for Wire Cable Trays in Different Environments

When selecting wire cable trays for various environments, installation is key. In industrial settings, trays must tolerate heavy loads and cable densities. According to a recent industry report, nearly 40% of electrical failures are linked to improper cable management. This highlights the need for careful planning during installation.

Tip: Ensure your cable tray has ample space for future expansion. It's better to overestimate space requirements. In commercial buildings, consider ventilation needs. Adequate airflow prevents overheating, especially in enclosed areas. Use trays with perforated designs or slots to enhance ventilation.

In residential settings, aesthetics might matter more. Choose trays that blend with interior designs. However, they still need to be functional. Proper grounding is essential, regardless of the space. A common mistake is neglecting to secure trays tightly. This can lead to sagging and damage over time. Reflecting on installation can save future headaches.

Related Posts

-

Best B Line Cable Tray Solutions for Efficient Cable Management

-

Exploring Innovative Alternatives to Traditional Cable Tray Wire Systems

-

Maximizing Safety and Efficiency: The Growing Demand for Basket Cable Trays in Modern Infrastructure

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

-

Ultimate Guide: How to Select the Right Flexible Cable Tray for Your Industrial Needs

-

5 Best Cable Tray Wire Solutions for Efficient Wiring Management

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now