Blog

Ultimate Guide to Choosing the Right Mesh Cable Tray for Your Project

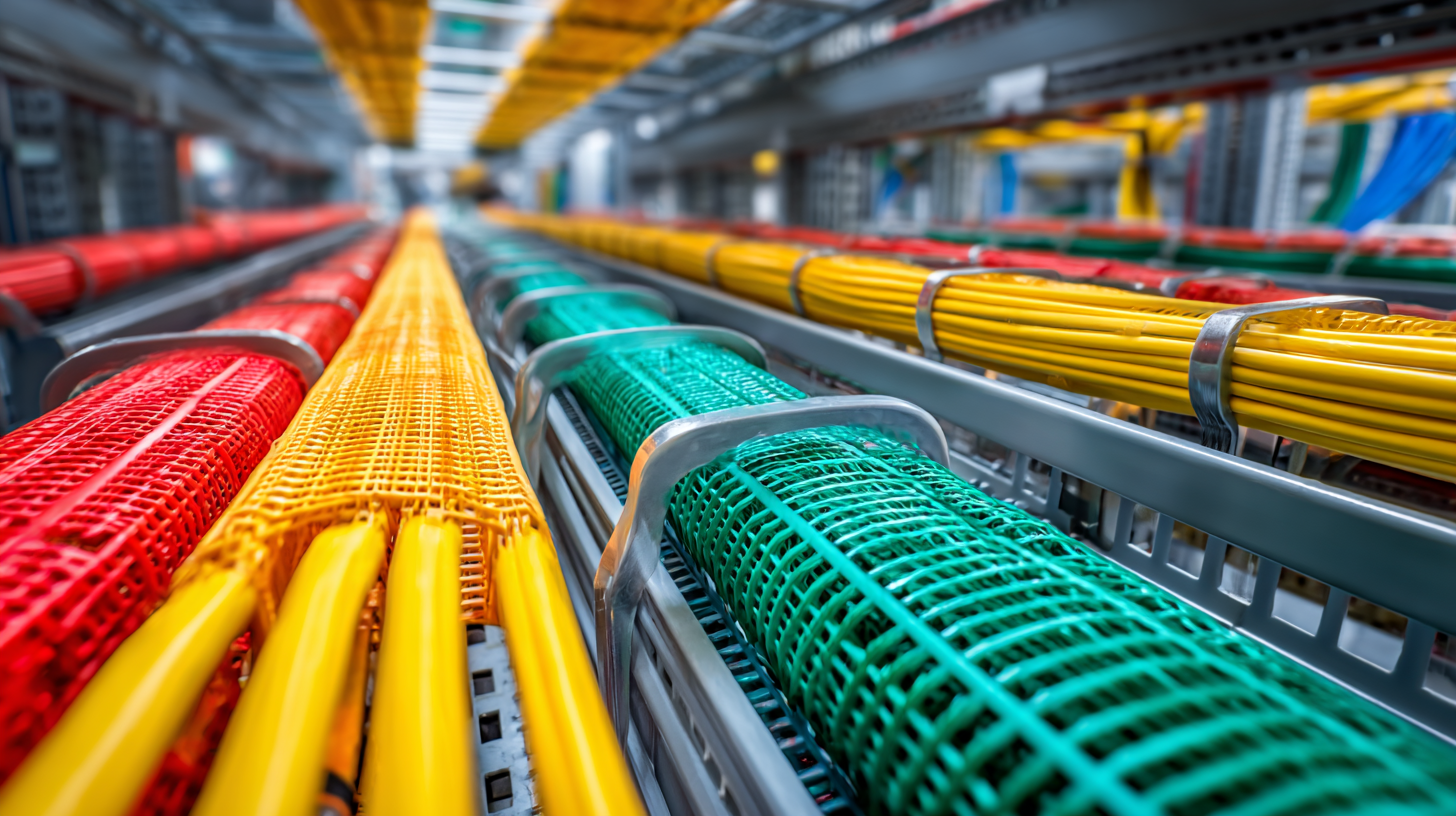

In the ever-evolving landscape of electrical infrastructure, selecting the appropriate mesh cable tray is crucial for ensuring optimal performance and safety in your project. According to a report by Research and Markets, the global cable tray market is projected to reach $7.48 billion by 2026, growing at a CAGR of 9.6% from 2021. This rapid growth highlights the importance of making informed decisions when it comes to cable management solutions. Mesh cable trays offer numerous advantages, including improved airflow, increased load capacity, and ease of installation, which makes them an increasingly preferred choice among engineers and project managers. Understanding the different types of mesh cable trays available, their applications, and selection criteria is essential for maximizing efficiency and compliance with industry standards. In this ultimate guide, we will delve into the key factors to consider when choosing the right mesh cable tray for your specific project needs.

Understanding the Different Types of Mesh Cable Trays Available Today

When selecting a mesh cable tray for your project, understanding the different types available is crucial. Mesh cable trays are often used for their flexibility, ease of installation, and ventilation properties. Among the most common types are wire mesh trays, ladder trays, and combo trays. Wire mesh trays provide excellent airflow and can support lightweight cables, making them ideal for data centers. Ladder trays, on the other hand, offer enhanced support for heavier loads and are suitable for larger installations.

Tip: Consider the environment in which the cable tray will be installed. For outdoor projects or places with high humidity, opt for trays with corrosion-resistant finishes.

Another important factor is the tray's size and load capacity. Make sure to choose a tray that can accommodate your project's specific cable requirements without compromising safety or performance. It's also worth looking at modular options, which allow for easy adjustments as your cable needs change over time.

Tip: Always consult with your electrical engineer or project manager to ensure compatibility between your cable types and the chosen mesh tray system.

Key Factors to Consider When Choosing a Mesh Cable Tray for Your Project

When choosing a mesh cable tray for your project, several key factors should guide your decision-making process. First, consider the load capacity. It's essential to select a tray that can support the weight of the cables and any additional equipment. This is particularly important in industrial applications where heavy cables are common. Review the specifications to ensure that the tray meets or exceeds the weight requirements of your installation.

Another critical aspect is the material of the mesh cable tray. Different materials, such as steel or aluminum, offer varying levels of strength, durability, and resistance to environmental factors like corrosion. If your project is located in a harsh environment, opting for coated or stainless steel trays may provide the longevity and performance needed. Additionally, think about the installation process; some trays come with more straightforward installation features that can save time and labor costs. By carefully evaluating load capacity, material, and ease of installation, you can select the right mesh cable tray that enhances efficiency and safety in your project.

Ultimate Guide to Choosing the Right Mesh Cable Tray for Your Project

| Feature | Description | Considerations |

|---|---|---|

| Material | Common materials include steel, aluminum, and fiberglass. | Choose based on durability and resistance to corrosion. |

| Load Capacity | Weight the mesh cable tray can support. | Assess the total weight of cables to avoid overloading. |

| Size and Dimensions | Length, width, and height specifications. | Ensure it fits your project’s layout and available space. |

| Installation Method | How the cable tray is mounted or suspended. | Consider ease of installation and required tools. |

| Ventilation | Ability to dissipate heat and allow airflow. | Important for preventing overheating of cables. |

| Compliance and Standards | Regulations and standards applicable to cable trays. | Ensure product meets local electrical and safety codes. |

Comparing Material Options for Mesh Cable Trays: Pros and Cons

When it comes to selecting a mesh cable tray for your project, understanding the material options available is crucial. The most commonly used materials for mesh cable trays include steel, aluminum, and plastic, each offering distinct advantages and disadvantages.

Steel trays, for instance, are known for their durability and strength, making them ideal for heavy-duty applications. However, they can be prone to rust if not properly coated, necessitating regular maintenance.

On the other hand, aluminum mesh trays are lightweight and resistant to corrosion, making them a popular choice for both indoor and outdoor installations. They provide a good balance of strength and weight, which can ease the installation process. However, one should note that aluminum can be more expensive than steel.

Plastic cable trays present an alternative that is lightweight and resistant to various environmental factors, such as moisture and chemicals. Nevertheless, they may lack the robustness required for heavy loads, making them suitable only for specific applications.

Evaluating these material options carefully will help ensure you choose the right mesh cable tray for your specific project needs.

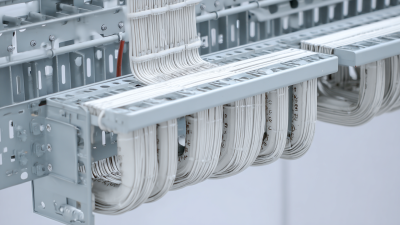

Installation Guidelines for Mesh Cable Trays: Tips for a Successful Setup

When it comes to installing mesh cable trays effectively, adherence to best practices is crucial for ensuring both safety and functionality in your project. According to recent industry reports, improper installation of cable trays can lead to significant cable damage and create hazards, impacting project timelines and budgets. Proper planning, from the layout to material selection, forms the backbone of a successful mesh cable tray setup. Ensure that you choose trays made from durable materials that can withstand environmental conditions, as studies indicate that corrosion-resistant trays can enhance longevity by up to 30%.

Installation guidelines should emphasize the importance of spacing and load capacities. The National Electrical Manufacturers Association (NEMA) recommends maintaining a specific distance between cable trays to avoid overcrowding, which can lead to heat buildup and reduced cable lifespan. Additionally, you should always confirm that the chosen tray can support the weight of the cables intended for installation; this is typically measured in pounds per linear foot. Following these recommendations not only contributes to a safer installation process but also optimizes the performance of your cabling system, supporting a more efficient operational environment in the long run.

Ultimate Guide to Choosing the Right Mesh Cable Tray

Maintaining Your Mesh Cable Tray: Best Practices for Longevity and Performance

Maintaining a mesh cable tray is essential for ensuring both longevity and optimal performance in any installation. To begin with, regular inspections should be a routine part of your maintenance plan. Look for signs of wear, corrosion, or damage that could compromise the integrity of the tray. Additionally, ensure that the tray is free of dust and debris, as accumulated materials can lead to overheating and affect the airflow necessary for optimal cable performance. Use a soft brush or vacuum to clean the tray without causing any scratches.

Another key aspect of maintenance is monitoring the load capacity. Overloading a mesh cable tray can lead to structural issues and premature failure. Always adhere to the manufacturer’s guidelines regarding load limits and ensure cables are arranged neatly to prevent sagging. If you notice any potential issues, consider adjusting the cable arrangements or redistributing weight to maintain balance. Implementing these best practices will not only extend the life of your mesh cable tray but also enhance its performance throughout your project.

Related Posts

-

How to Select the Right Basket Cable Tray for Your Wiring Needs

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

-

The Future of Plastic Cable Tray Innovations and Sustainability

-

Ultimate Guide: How to Select the Right Flexible Cable Tray for Your Industrial Needs

-

Understanding the Challenges of Wire Cable Tray Systems: Insights and Solutions from Industry Experts

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now