Blog

How to Choose the Right Black Cable Tray for Your Wiring Needs

In today's rapidly evolving electrical installation landscape, selecting the appropriate black cable tray is critical for ensuring both efficiency and safety. According to a recent market research report by Research and Markets, the global cable tray market is projected to reach USD 7.3 billion by 2028, with a significant emphasis on metal cable trays, where black cable trays are commonly preferred for their durability and aesthetic appeal. These trays not only organize and protect wiring systems but also contribute to effective heat dissipation, thereby prolonging the life of cables. Additionally, industry standards such as those set by the National Electrical Manufacturers Association (NEMA) underline the importance of using the right materials and designs to meet specific wiring needs. By understanding the various types, sizes, and materials available, professionals can make informed choices that enhance the functionality of their installations while adhering to safety regulations.

Understanding the Different Types of Black Cable Trays Available

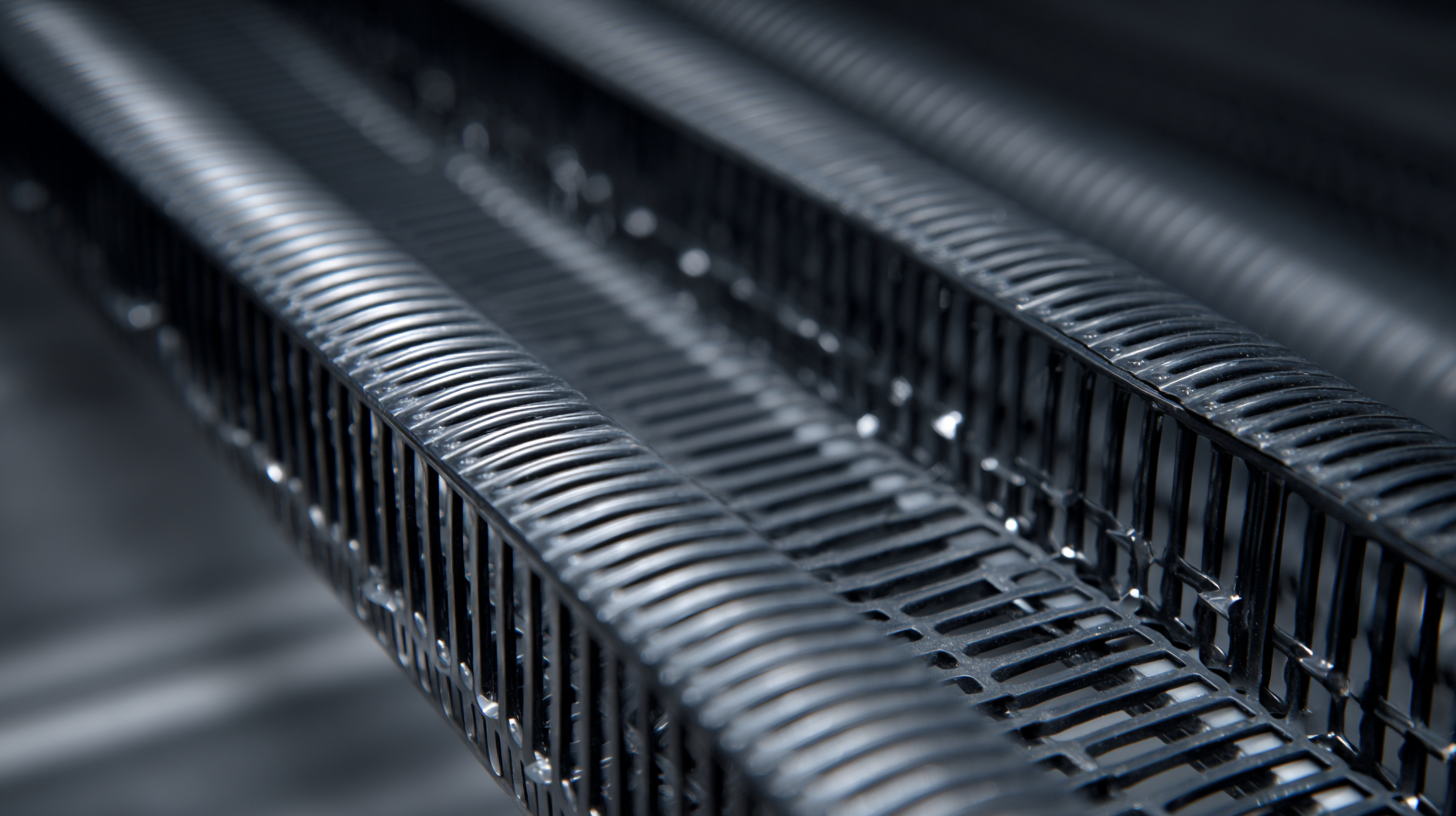

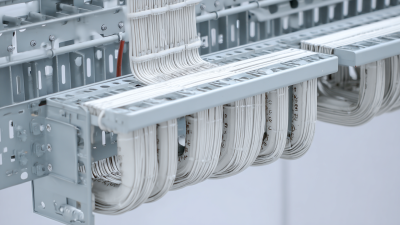

When selecting the right black cable tray for your wiring needs, it's essential to understand the various types available on the market. Cable trays are crucial for organizing and protecting electrical wires, ensuring both safety and efficiency. The most common types include ladder, perforated, and solid-bottom cable trays, each serving different applications.

Ladder cable trays are ideal for heavy-duty wiring projects, providing excellent ventilation and support for large cables. Their open design allows for easy access and modification, making them a popular choice for industrial settings. On the other hand, perforated trays are designed for lighter applications, offering a balance of support and air circulation. These trays are versatile and suitable for buildings with less demanding wiring systems. Solid-bottom trays provide a continuous surface, making them suitable for environments where dust and debris are concerns, as they help protect the cables from contaminants.

Understanding these different types of black cable trays will help you make an informed choice, ensuring that the selected option aligns with your specific wiring needs and installation environment.

Assessing Your Wiring Needs and Load Requirements

When selecting a black cable tray, the first step is to thoroughly assess your wiring needs. Consider the type and quantity of cables you plan to run, as this will significantly influence the size and design of the cable tray. For instance, if your setup includes various sizes of cables or additional components such as conduits, you may need a tray that features adjustable dividers or wider dimensions to accommodate your requirements. Additionally, evaluating the environment in which the cables will be installed is crucial. Factors such as exposure to heat, moisture, or corrosive elements can dictate the materials used in the cable tray, ensuring a longer lifespan and minimizing maintenance costs.

Load requirements are another critical aspect to consider. Each cable tray has a specified load capacity, meaning it can only support a certain amount of weight before it risks failure. To prevent future complications, it is essential to calculate the total weight of the cables, including any additional accessories like connectors or junction boxes. Make sure to account for any future expansions in wiring, as oversizing the cable tray can provide flexibility for future projects. This calculated approach ensures that your cable tray installation is not only safe but also aligned with your current and evolving electrical needs.

Factors to Consider: Material, Size, and Installation Environment

When choosing the right black cable tray for your wiring needs, size and material are crucial factors to consider. The global demand for lightweight materials, which include the materials used in cable trays, is projected to grow significantly. In 2023, the lightweight materials market was valued at approximately $137.09 billion, with projections indicating an increase to $143.4 billion by 2024, and a compound annual growth rate (CAGR) of 5.15% through 2031. This growth reflects the increasing preference for materials that offer strength without the added weight, enhancing efficiency in installation and use.

Moreover, specific market segments, such as fiberglass products, are demonstrating strong potential. The fiberglass pool market alone is anticipated to reach a global size of $12.58 billion in 2024, underscoring the rising popularity and application of innovative materials. As businesses and individuals increasingly look for durable yet lightweight solutions, understanding the material properties and appropriate sizing of cable trays will directly impact performance and longevity in various installation environments. This awareness can support informed decisions that align with both current trends and future demands in construction and electrical applications.

Evaluating Cost vs. Quality in Cable Tray Selection

When selecting a black cable tray for your wiring needs, evaluating cost versus quality is crucial. While budget constraints are always a consideration, opting for the cheapest option may lead to long-term issues such as durability and reliability. Quality cable trays are designed to withstand environmental factors and support the weight of cables without sagging or breaking. Therefore, it's essential to consider the intended use and potential stress the trays will encounter.

Tips: Always verify the material of the cable tray; galvanized steel or aluminum typically offers better resistance to corrosion, ensuring longevity. Additionally, reviewing product warranties can provide insight into the manufacturer's confidence in their quality. Investing in a slightly more expensive product may save you from future repairs and replacements, ultimately proving more economical.

Another aspect to consider is compliance with industry standards. High-quality cable trays often adhere to strict safety and performance guidelines, reducing risks in your wiring setup. It’s worth looking into certifications and testing results to ensure you're making a well-informed decision.

Tips: Create a checklist of required features based on your specific applications, such as load capacity and installation environment, to help narrow down your options effectively.

Best Practices for Maintenance and Safety Compliance

When selecting the right black cable tray for your wiring needs, maintenance and safety compliance should be at the forefront of your decision-making process. According to the National Fire Protection Association (NFPA), improper cable management can lead to increased fire hazards, with electrical failures accounting for approximately 6% of all residential fires in the United States. Regular inspections and maintaining a clean environment around your cable trays can significantly mitigate these risks. Keeping cables organized not only enhances safety but also improves accessibility for future maintenance and upgrades.

Best practices include ensuring that the cable trays are compatible with the cables being used, taking into account both weight and heat dissipation requirements. The National Electrical Manufacturers Association (NEMA) standards highlight that cable trays should be evaluated for load capacity and should be regularly monitored for any signs of wear or damage. Additionally, it's crucial to apply proper grounding techniques and use non-combustible materials where possible, as this greatly enhances compliance with safety regulations. By adhering to these guidelines, you can optimize your cable tray system's performance while safeguarding your facility from potential hazards.

Black Cable Tray Selection Criteria

This bar chart illustrates key selection criteria for black cable trays based on various specifications such as load capacity, material durability, cost, installation time, and safety compliance. These factors are essential in determining the most suitable cable tray for specific wiring needs.

Related Posts

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

-

The Future of Plastic Cable Tray Innovations and Sustainability

-

Ultimate Guide: How to Select the Right Flexible Cable Tray for Your Industrial Needs

-

How to Select the Right Basket Cable Tray for Your Wiring Needs

-

Understanding the Challenges of Wire Cable Tray Systems: Insights and Solutions from Industry Experts

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now