Blog

How to Choose the Right Floor Cable Tray for Your Needs?

Choosing the right floor cable tray is essential for efficient cable management in modern infrastructures. According to a report by MarketsandMarkets, the global market for cable trays is projected to reach $3 billion by 2025, driven by the rise in construction activities. This growth highlights the increased demand for effective cable management solutions.

Industry expert John Smith states, "Selecting the correct floor cable tray can enhance safety and improve system performance." His insight emphasizes the importance of not just aesthetic but functional choices. For instance, materials like steel and fiberglass each have their unique advantages, suitable for different environments.

However, many still overlook crucial factors. Not everyone considers load capacity or environmental conditions. This oversight can lead to costly mistakes. Ensuring a suitable size and design for the specific application is critical. Thoughtful consideration can prevent future issues, allowing for seamless operations and maintenance. It's vital to reflect on one’s choices in the selection process.

Understanding the Purpose of Floor Cable Trays

Floor cable trays serve a crucial role in modern electrical installations. They provide a structured pathway for organizing and supporting cables. This organization helps reduce clutter and potential hazards. A well-designed cable tray system can improve accessibility for maintenance and upgrades. This is particularly important in commercial environments where efficiency is vital.

Choosing the right cable tray involves understanding your specific needs. Consider the type and volume of cables. Different materials and designs cater to various environments. For instance, metal trays are durable but may not be suitable for all settings. Plastic options offer flexibility but may not hold up in heavy-duty applications.

One common oversight is underestimating cable expansion and contraction. Environmental factors can cause cables to shift. This can lead to tangling or damage over time. Reflect on how cable management affects your workflow. Taking these details into account will guide you towards an effective solution.

Identifying Different Types of Floor Cable Trays

When selecting a floor cable tray, understanding the various types is essential. The three main categories are solid bottom trays, ladder trays, and perforated trays. Solid bottom trays offer excellent structural integrity. They provide a robust design, ideal for heavy cabling. However, they can retain heat and moisture, which may pose challenges.

Ladder trays, on the other hand, are popular for supporting cables over long distances. They allow air circulation, reducing heat buildup. According to the National Electrical Manufacturers Association (NEMA), using ladder trays can improve cable longevity by 30%. Still, the open design can expose cables to dust and debris, which may require additional maintenance.

Perforated trays combine the benefits of both designs. They allow for air circulation while offering some protection. These trays are versatile and can adapt to various installations. Yet, their installation can sometimes be tricky due to weight distribution. Selecting the right tray comes down to specific project needs, including cable type and environmental conditions. The choice impacts not only performance but also maintenance requirements.

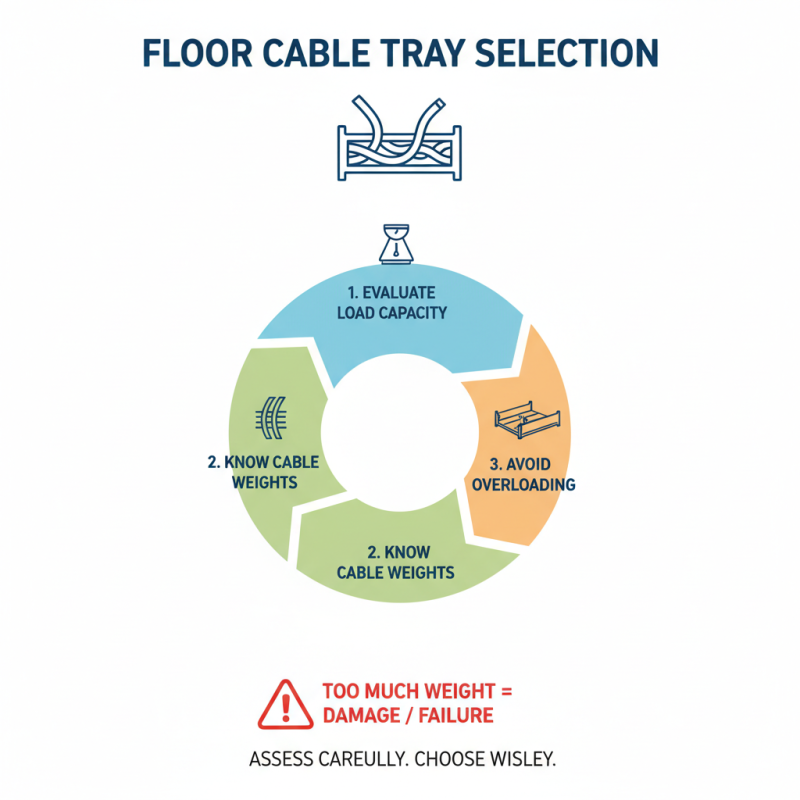

Evaluating Load Capacity and Material Durability

When selecting a floor cable tray, evaluating its load capacity is crucial. Each tray has a specific weight it can safely hold. It's important to know the weight of the cables and other components. This knowledge helps avoid overloading issues. Too much weight can lead to damage or failure. A tray that cannot support the load may bend or break. So, conduct a careful assessment before making a decision.

Material durability affects the longevity of your cable tray. Different materials have varying resistance to wear and environmental factors. For instance, metal trays may resist impacts better than plastic ones. However, they could corrode in humid conditions. Choosing the right material entails analyzing where the tray will be installed. Consider potential hazards, such as chemicals and moisture.

Additionally, don’t overlook the tray's installation process. It can be challenging if the tray is too heavy or bulky. Making the right choice means weighing durability against ease of use. A durable tray could be difficult to work with. Balancing these factors is vital. Reflect on the specific needs of your project before committing to a type.

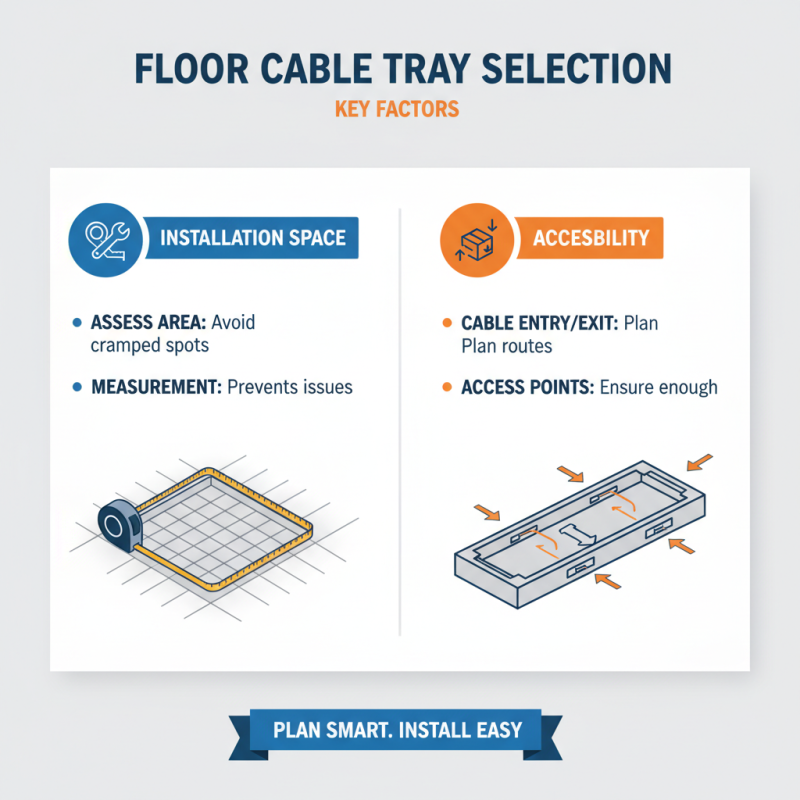

Considering Installation Space and Accessibility

When selecting a floor cable tray, installation space and accessibility are crucial factors. You need to assess the area where you will install the tray. A cramped space can complicate installation. Careful measurement minimizes future frustrations. Consider how cables will enter and exit the tray. Adequate access points are essential.

Accessibility also affects maintenance. If the cable tray is hard to reach, troubleshooting becomes challenging. Ensure there’s enough room for cable management. Plan for future upgrades or changes. Sometimes, an ideal layout in theory may not work in practice. Mocking up a visual representation could highlight potential issues.

Lastly, think about safety. A poorly installed tray can pose risks. Take time to review local regulations. It might seem tedious, but safety shouldn’t be overlooked. Your choice impacts both functionality and safety. Don’t rush; reflect on your installation needs carefully.

Assessing Cost and Compliance with Safety Standards

When selecting a floor cable tray, safety compliance is crucial. Many industries must adhere to standards like NEC or IEC. Studies show that nearly 30% of electrical failures can be traced back to inadequate cable management. Choosing the right tray ensures not just efficiency but also safety.

Cost is another key factor. A report from a leading industry analyst indicates that proper cable management can reduce maintenance costs by up to 20%. This is significant in large facilities where downtime can be costly. However, one might feel tempted to opt for cheaper solutions. These budget options might lack the necessary compliance features. Non-compliance can lead to fines or, worse, unsafe working conditions.

Choosing a tray requires a balance. Understand the specific requirements of your installation. Look into the materials used. Steel and aluminum trays have different cost implications and durability. Reflecting on these factors can prevent future issues. Making choices based solely on price can result in regrettable situations. It’s essential to weigh cost against safety standards.

Cost Comparison of Different Floor Cable Trays

This chart compares the average cost per meter of various types of floor cable trays. It helps in assessing which material might best fit budget considerations while ensuring safety standards are met.

Related Posts

-

Ultimate Guide: How to Select the Right Flexible Cable Tray for Your Industrial Needs

-

Maximizing Safety and Efficiency: The Growing Demand for Basket Cable Trays in Modern Infrastructure

-

2025 Top 10 Electrical Cable Tray Innovations You Can't Miss

-

Top 10 Benefits of Using Cable Tray for Your Electrical Wiring Needs

-

How to Choose the Right Ladder Cable Tray for Your Project?

-

Top 10 Benefits of Using Cable Tray Wire for Efficient Wiring Solutions

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now