Blog

5 Best Reasons to Choose Fiberglass Cable Tray for Your Next Project

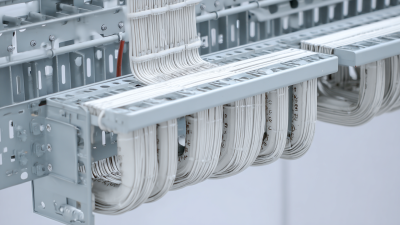

When it comes to selecting the right materials for your next construction or electrical project, the choice of cable management plays a crucial role in ensuring safety, efficiency, and durability. Among the various options available in the market, fiberglass cable tray stands out as a premier solution. This innovative material offers remarkable advantages that not only enhance performance but also provide long-term cost savings.

In this blog, we will explore the five best reasons why fiberglass cable tray should be at the top of your list when considering cable management options. From its exceptional strength-to-weight ratio to its resistance to corrosion and environmental factors, fiberglass cable trays are designed to meet the stringent demands of modern projects. Join us as we dive into this comparative analysis and discover why fiberglass cable tray could be the perfect choice for your upcoming ventures.

Advantages of Fiberglass Cable Trays Over Traditional Materials

Fiberglass cable trays have gained significant traction in various industries due to their remarkable advantages over traditional materials like steel and aluminum. The global market for fiberglass cable trays is expected to grow at a CAGR of 6.2%, reaching $650 million by 2025, indicating a shift in preference towards innovative materials. Fiberglass offers a high strength-to-weight ratio, making it easier to install and manage in both commercial and industrial settings. This lightweight characteristic not only reduces labor costs but also enhances overall project efficiency.

Another critical advantage of fiberglass cable trays is their resistance to corrosion and harsh environmental conditions. Unlike traditional metal trays, fiberglass does not rust or corrode, even in chemically aggressive environments. A report from Research and Markets shows that maintenance costs can be reduced by up to 30% when using fiberglass solutions, particularly in industries such as pharmaceuticals, chemicals, and wastewater management, where exposure to corrosive substances is common. Additionally, the non-conductive properties of fiberglass significantly diminish safety risks in electrical installations, making it a preferred choice in sectors requiring stringent safety measures.

Durability and Resistance: Why Fiberglass Stands the Test of Time

Fiberglass cable trays have emerged as a superior choice for modern construction projects, primarily due to their exceptional durability and resistance properties. The integration of three layers of emulsion bitumen with fiberglass has been shown to enhance concrete durability by over 90%, particularly when subjected to harsh conditions such as severe chloride exposure. This impressive performance is a testament to the material's ability to withstand aggressive environments, ensuring that installations remain intact and effective over the long term.

In addition to their physical resilience, fiberglass cable trays exhibit remarkable chemical resistance, making them ideal for various industrial applications. When compared with conventional materials, fiberglass demonstrates a higher tolerance to corrosive substances, a crucial factor for projects involving exposure to harsh chemicals. This adaptability not only extends the lifespan of the infrastructure but also contributes to lower maintenance costs, further solidifying fiberglass as a smart investment in sustainable building practices. As technological advancements continue to evolve, the move towards incorporating fiberglass in cable tray systems reflects a broader trend in construction towards enhanced performance and environmental responsibility.

5 Best Reasons to Choose Fiberglass Cable Tray for Your Next Project

| Reason | Description | Benefits | Application |

|---|---|---|---|

| Durability | Fiberglass is highly resistant to corrosion and environmental factors. | Longer lifespan, lower maintenance costs. | Ideal for industrial settings with harsh conditions. |

| Lightweight | Easier to handle and install compared to metal trays. | Reduced labor costs and faster installation time. | Suitable for various commercial and residential projects. |

| Non-conductive | Fiberglass does not conduct electricity. | Increased safety in electrical installations. | Preferred in electrical systems and substations. |

| Fire Resistance | Fiberglass trays have non-combustible properties. | Enhanced fire safety and compliance with regulations. | Applicable in high-risk environments. |

| Cost-effectiveness | Lower total cost of ownership due to durability and low maintenance. | Saves money in the long run. | Ideal for budget-conscious projects. |

Cost-Effectiveness: Long-Term Savings with Fiberglass Solutions

When considering materials for your next cable management project, fiberglass cable trays stand out for their cost-effectiveness. While the initial investment might appear higher than traditional materials, the long-term savings they offer are significant. Fiberglass is highly resistant to corrosion, which means lower maintenance costs and a longer lifespan. This durability translates to fewer replacements and repairs over time, making fiberglass an economical choice for projects that require longevity.

Additionally, fiberglass cable trays are lightweight and easy to install, which can reduce labor costs during installation. The ease of handling these trays minimizes time on site, allowing for quicker project completion. Furthermore, their non-conductive properties make them ideal for electrical installations, mitigating the risk of electrical hazards and additional expenses related to safety measures. Overall, utilizing fiberglass cable trays not only offers immediate benefits but also ensures substantial savings over the entire lifespan of your project, making it a smart investment choice.

Cost-Effectiveness of Fiberglass Cable Tray: Long-Term Savings

This chart illustrates the different cost factors associated with fiberglass cable trays. Key areas assessed include material costs, installation expenses, maintenance, lifespan savings, and environmental impact costs. Choosing fiberglass solutions can lead to substantial long-term financial benefits.

Ease of Installation: Streamlining Your Project with Fiberglass Cable Trays

When it comes to streamlining your installation process, fiberglass cable trays offer significant advantages over traditional materials. Their lightweight nature allows for easy handling and maneuvering on site, reducing labor costs and time. Fiberglass cable trays are also resistant to corrosion, which means they can be installed in challenging environments without the worry of degradation, further simplifying the setup process.

**Tip:** Always ensure that you have the right installation tools handy before starting your project. Having the necessary tools readily available can prevent delays and keep the process efficient. Additionally, consider organizing your workspace to avoid clutter, which can slow down the installation.

Fiberglass cable trays are designed for straightforward assembly, allowing your team to focus on the project rather than getting bogged down by complicated setups. Their modular design can easily adapt to different layouts and requirements, ensuring a perfect fit for any installation scenario.

**Tip:** Take advantage of the modularity by planning your cable tray layout carefully. Mapping out the installation ahead of time not only saves time but also helps in identifying any potential challenges early in the process. This foresight can lead to a smoother and quicker installation, further enhancing your project's efficiency.

Environmental Benefits: Choosing Sustainable Options for Your Project

When considering materials for your next project, opting for fiberglass cable trays not only provides structural benefits but also aligns with sustainable practices. One of the key environmental advantages of fiberglass is its longevity. Unlike metal trays that may corrode over time, fiberglass offers resistance to rust and degradation, reducing the need for frequent replacements. This durability means less waste and fewer resources consumed over the lifespan of the installation.

Tip: When choosing fiberglass cable trays, look for manufacturers that utilize recycled materials in their production process. This not only enhances the sustainability of your project but also supports a circular economy.

Another significant benefit is the lightweight nature of fiberglass, making it easier to transport and install. This reduced weight translates to lower carbon emissions during transportation and less energy required for installation. Additionally, fiberglass's non-conductive properties enhance safety, reducing the risk of electrical hazards in your project.

Tip: Ensure proper recycling practices are in place for any fiberglass waste generated during installation. By adopting these practices, you can further minimize your project's environmental impact and promote a cleaner, greener approach.

Related Posts

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

-

Quality Tray Cables from China: Elevating Global Standards with Exceptional Manufacturing

-

The Future of Plastic Cable Tray Innovations and Sustainability

-

Understanding the Challenges of Wire Cable Tray Systems: Insights and Solutions from Industry Experts

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now