Blog

Best B Line Cable Tray Solutions for Efficient Cable Management

In the rapidly evolving landscape of electrical installations, efficient cable management has become increasingly critical. The market for cable management solutions, including B Line cable trays, is projected to grow significantly as industries seek to improve safety and streamline operations. According to a recent market research report, the global cable tray market is expected to reach USD 5.5 billion by 2025, rising at a compound annual growth rate (CAGR) of 7.2%. This growth is driven by the expanding energy sector and the rising need for organizational systems in commercial and industrial settings.

B Line cable trays offer a robust and versatile solution for managing electrical cabling, ensuring that installations remain both effective and accessible. Utilizing B Line cable trays helps to mitigate the risks associated with cable damage, which can lead to costly downtimes and safety hazards. Industry studies indicate that well-implemented cable management systems can reduce maintenance costs by up to 30%, underscoring the value of adopting reliable solutions. As we explore the best B Line cable tray solutions available, it's essential to recognize their role not only in enhancing operational efficiency but also in fortifying workplace safety standards amid growing demands in various sectors.

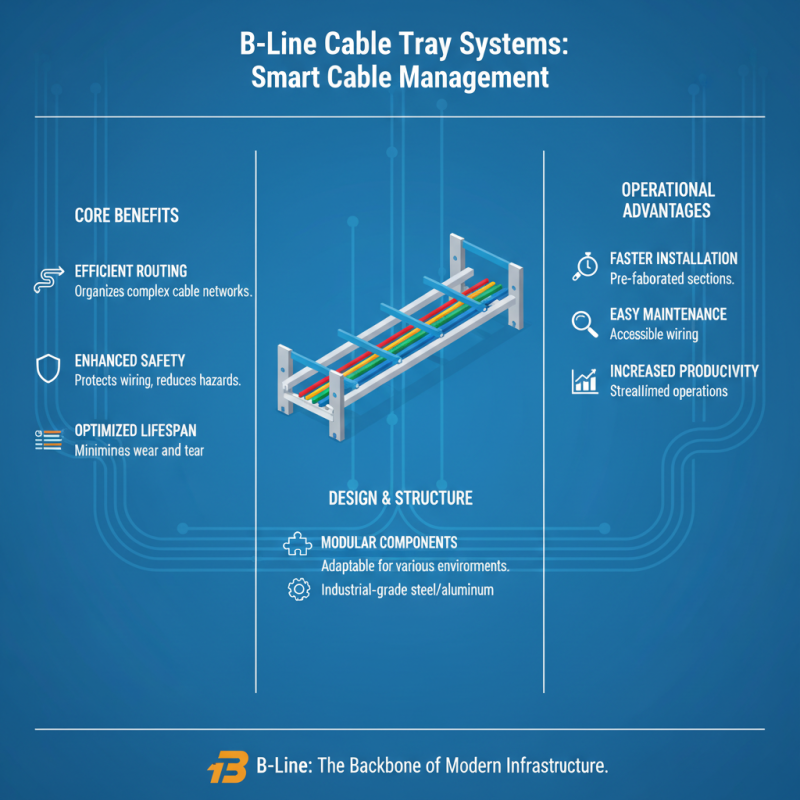

Understanding B Line Cable Tray Systems for Optimal Cable Management

B Line cable tray systems offer an efficient solution for managing the complex networks of cables in modern facilities. These systems are designed to support, route, and protect wiring in industrial, commercial, and institutional environments, where organized cable management is crucial for both safety and operational efficiency. Understanding the structure and design of B Line cable tray systems can lead to higher productivity and streamlined installations, as they not only facilitate easier access for maintenance but also maximize cable lifespan by reducing wear and tear.

When selecting a B Line cable tray solution, one must consider factors such as the material, load capacity, and installation environment. For instance, materials vary from galvanized steel to fiberglass-reinforced plastic, each suited for different applications based on resistance to corrosion, temperature fluctuations, and overall strength. The tray's design—whether it be ladder-style, single rail, or basket-type—also plays a significant role in determining how effectively cables can be arranged and managed. By prioritizing these elements, facilities can achieve optimal cable management that promotes longevity and reduces the risk of complications related to disorganized or exposed cabling.

Key Features of B Line Cable Tray Solutions for Versatile Installation

B Line cable tray solutions are designed with a range of key features that ensure versatile installation in various environments. One of the most notable characteristics is the modular design, which allows for easy customization and expansion to accommodate growing cable management needs. This adaptability is crucial in dynamic settings where systems often require updates or modifications. The integration of multiple accessories, such as elbows and cross members, further enhances the flexibility of these cable trays, enabling seamless routing of cables around obstacles and into diverse configurations.

Additionally, the materials used in B Line cable trays are selected for durability and performance, ensuring they can withstand various environmental conditions. Options like steel, aluminum, and fiberglass provide choices that cater to specific project requirements, such as weight considerations and resistance to corrosion or heat. The ease of installation is another significant feature, as many B Line solutions utilize quick-mount systems and pre-punched designs, which minimize labor costs and project time. This combination of features not only facilitates efficient cable management but also supports compliance with safety standards, making B Line cable tray solutions a reliable choice for any installation project.

Best B Line Cable Tray Solutions for Efficient Cable Management

| Feature | Description | Advantages | Application |

|---|---|---|---|

| Material | Steel, Aluminum, or PVC options | Durability, Corrosion Resistance, Lightweight | Commercial, Industrial, Residential |

| Load Capacity | Varied load ratings available | Safety, Reduced Risk of Collapse | Data Centers, Manufacturing Plants |

| Installation Flexibility | Supports multiple configurations | Easier installation and modifications | Various Environments |

| Fire Rating | Certified for fire safety | Compliance with regulations | High-Risk Areas |

| Finishing Options | Painted, Galvanized, or Coated | Aesthetic appeal and protection | Architecturally Designed Spaces |

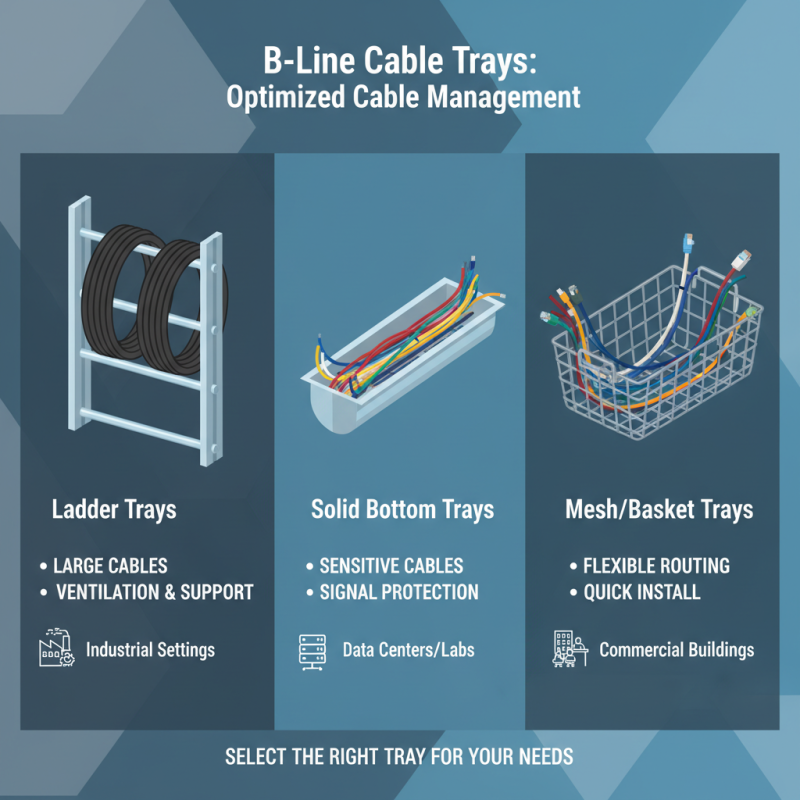

Comparing Different Types of B Line Cable Trays for Specific Needs

When it comes to efficiently managing cables in various environments, selecting the right type of B Line cable tray is crucial. Each type of tray offers distinct advantages tailored to specific needs. For instance, ladder trays are ideal for large cables as they provide excellent ventilation and support, ensuring cables stay cool and are easy to install. This makes ladder trays a preferred choice in industrial settings where heavy-duty cables are prevalent.

In contrast, solid-bottom trays offer superior protection against dust and debris, making them suitable for cleanroom environments or areas requiring high levels of hygiene. These trays can support smaller, delicate cables and are designed to minimize wear and tear. Additionally, some types of B Line cable trays, such as wire mesh trays, provide both versatility and accessibility, allowing for easy adjustments and rearrangements based on evolving cabling needs.

For optimal cable management, it is essential to assess the specific requirements of the installation environment, including factors like cable size, weight, and the potential for future changes. By carefully comparing the different types of B Line cable trays, users can make informed decisions that enhance both efficiency and longevity in their cable management systems.

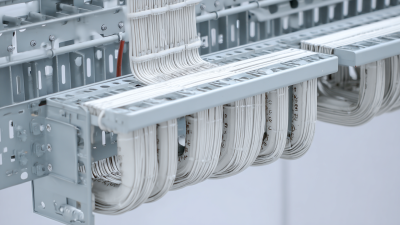

Installation Best Practices for B Line Cable Tray Systems

When installing B Line cable tray systems, adhering to best practices is crucial for ensuring optimal performance and safety. According to a report by the National Electrical Contractors Association (NECA), improper installation of cable management systems can lead to increased maintenance costs and safety risks, with potential increases in downtime for electrical systems. One key aspect of installation involves proper spacing and support; the trays should be installed in such a way that they can bear the weight of the cables efficiently.

For instance, regulatory guidelines suggest that support should be provided at maximum intervals of 10 feet for horizontal runs, significantly reducing the risk of sagging and electrical hazards.

Additionally, careful planning and layout design are essential for maximizing the efficiency of B Line cable trays. A study published in the Electrical Reliability Council of Texas (ERCOT) emphasizes that a well-planned cable management system can improve airflow and thermal dissipation, which are vital for maintaining the longevity of electrical installations. It's recommended to group cables based on their applications and voltage ratings, thus minimizing electromagnetic interference and enhancing system reliability. Implementing these best practices not only streamlines cable installation but also ensures compliance with industry safety standards, ultimately contributing to a more efficient electrical infrastructure.

Maintenance Tips for Longevity and Efficiency of Cable Trays

Maintaining cable trays is essential for ensuring their longevity and efficiency in managing electrical and communication cables. One effective tip is to conduct regular inspections of the cable trays. This involves checking for any signs of wear, damage, or corrosion, particularly in areas where cables may rub against the tray or where environmental factors may cause deterioration. Addressing these issues promptly can prevent more significant problems down the line, ensuring that the cable management system operates smoothly.

Another crucial aspect of maintenance is keeping the trays clean and free from dust and debris. Accumulation of dirt can lead to overheating and increased resistance in electrical cables, which may compromise their performance. Implementing a scheduled cleaning routine, using non-abrasive methods, can help maintain optimal airflow and minimize the risk of equipment failure. Additionally, ensuring that cables are organized and evenly spaced within the trays can prevent tangling and reduce stress on the cables themselves, enhancing the overall efficiency of the system.

Lastly, it’s important to assess the weight load of the cables placed in the trays. Overloading can lead to structural failure, so regularly reviewing load requirements according to manufacturer guidelines or industry standards is essential. By adhering to these maintenance tips, users can significantly extend the lifespan of their cable tray systems while ensuring that they operate at peak efficiency.

Related Posts

-

Understanding the Importance of Cable Tray Wire in Modern Electrical Installations

-

Ultimate Guide: How to Select the Right Flexible Cable Tray for Your Industrial Needs

-

How to Choose the Right Black Cable Tray for Your Wiring Needs

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

Maximizing Safety and Efficiency: The Growing Demand for Basket Cable Trays in Modern Infrastructure

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now